産(chǎn)品丨赢創尼龍微粉在塗料中(zhōng)的應用(yòng)

發布時間:

2025-01-17

在塗料領域,材料的創新(xīn)應用(yòng)是推動行業發展的核心動力之一,尼龍微粉 PA12 憑借其獨特的物(wù)理(lǐ)化學(xué)特性,正逐漸成為(wèi)塗料配方中(zhōng)的關鍵成分(fēn),為(wèi)塗料性能(néng)的全方位提升開辟了新(xīn)路徑。

尼龍微粉 PA12 具(jù)備高度的耐磨性,這一特性在諸如工(gōng)業環境,家具(jù)地闆木(mù)器等領域的塗料應用(yòng)中(zhōng)表現得尤為(wèi)突出。

在工(gōng)業環境中(zhōng),機器設備的表面塗層需要承受頻繁的摩擦與磨損,PA12 微粉的融入顯著增強了塗料的耐磨性能(néng),形成的塗層能(néng)夠有(yǒu)效抵抗金屬工(gōng)具(jù)的刮擦、物(wù)料的沖擊以及機械運轉過程中(zhōng)的持續摩擦,從而延長(cháng)設備的使用(yòng)壽命,減少維修與更換的頻次,降低企業的運營成本。

在木(mù)器塗料方面,尼龍微粉 PA12 也發揮着獨特的作(zuò)用(yòng)。它能(néng)夠為(wèi)木(mù)器表面提供一層堅韌且具(jù)有(yǒu)一定柔韌性的保護膜,不僅提升了木(mù)器的耐磨性,使其在日常使用(yòng)中(zhōng)不易被劃傷磨損,還能(néng)增強塗料對木(mù)器紋理(lǐ)的潤濕性和附着力,讓木(mù)器的天然紋理(lǐ)更加清晰美觀,同時有(yǒu)效防止水分(fēn)侵入木(mù)材内部,減少木(mù)材因受潮而變形、腐朽的風險,延長(cháng)了木(mù)器家具(jù)的使用(yòng)壽命,提升了其品質(zhì)和價值。

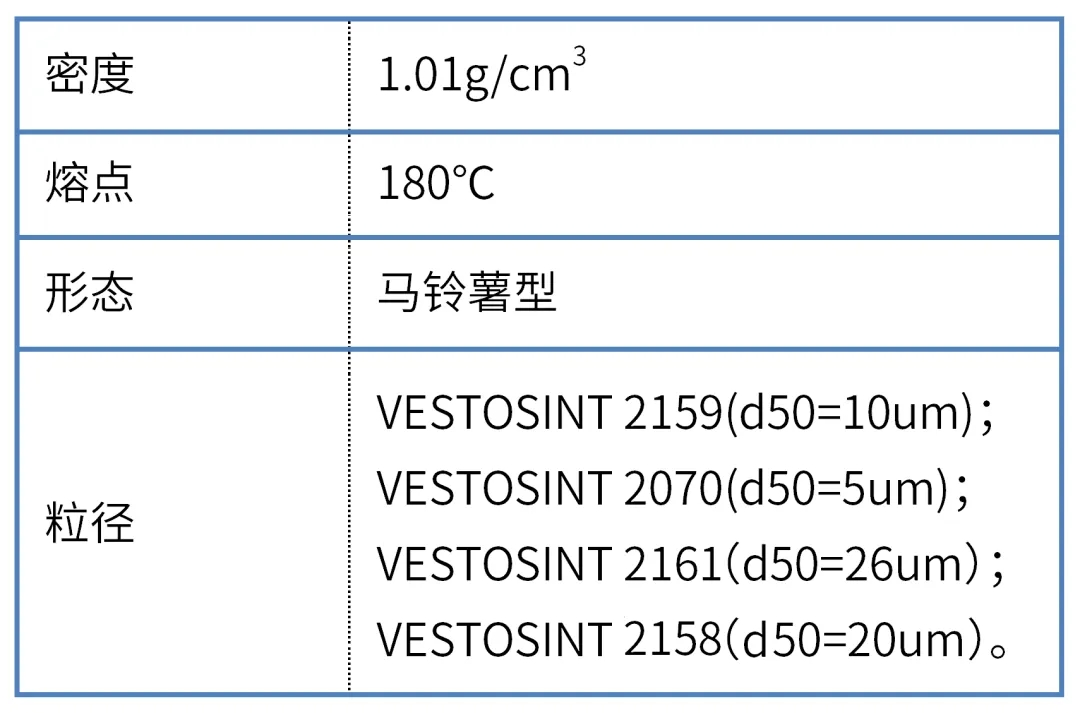

尼龍微粉是種熱塑性聚合物(wù)粉末,它的物(wù)理(lǐ)特性如下:

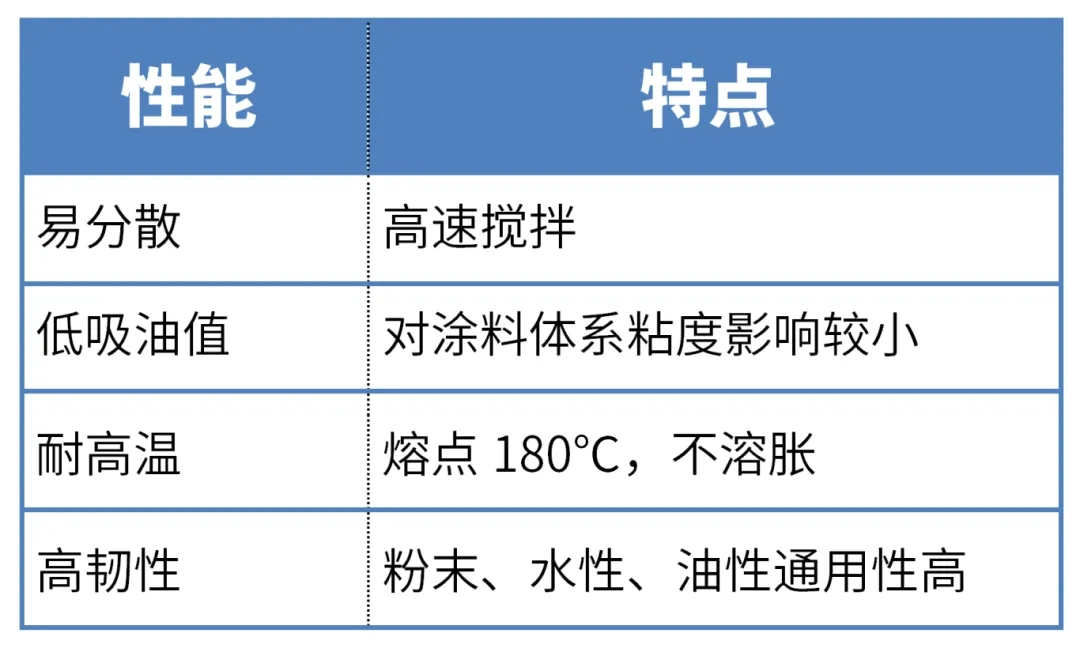

02 赢創尼龍微粉的性能(néng)特點:

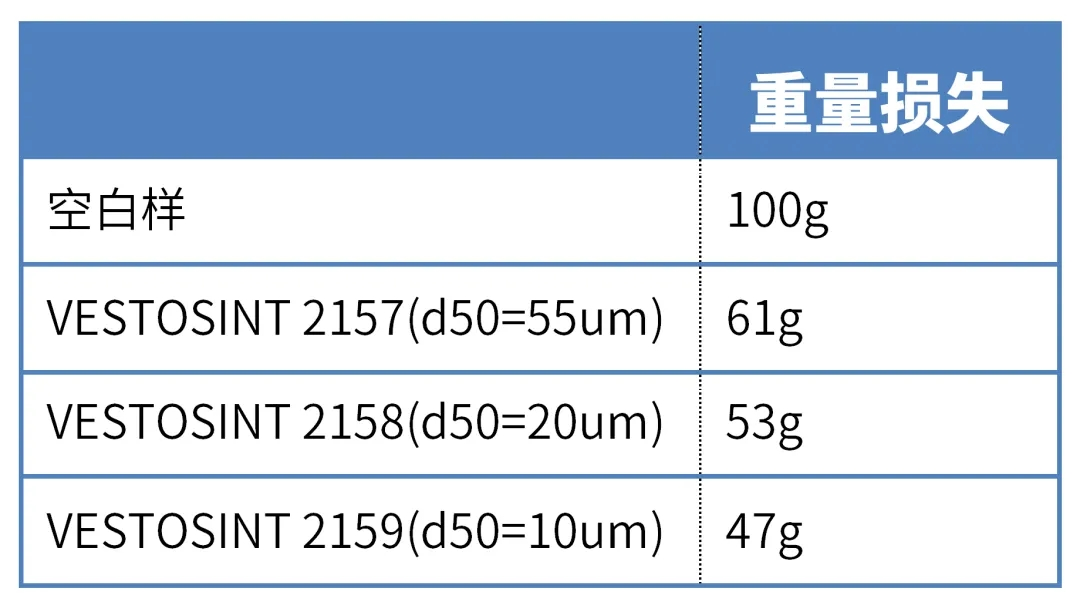

03 赢創尼龍微粉給塗層帶來塗層耐磨性能(néng)改善:

PA12微粉能(néng)在塗料表面形成低表面能(néng)的光滑塗層,可(kě)以增加戶外設備的耐沾污效果。

問答(dá)環節

問:尼龍微粉如何添加,是否水油通用(yòng)?

答(dá):高速分(fēn)散階段加入即可(kě),水油通用(yòng)。

版權所有(yǒu) © 2022 上海海逸科(kē)貿有(yǒu)限公(gōng)司