Application of easily dispersible fumed silica in industrial coatings

Release Time:

2021-09-15

Easily dispersible fumed silica

As a common rheology additive, fumed silica is widely used in solvent-based coatings and water-based coatings. Traditional fumed silica inevitably requires a grinding process during use to achieve the fineness required by the coating. Energy consumption and time during the grinding process are also costs.

In this regard, Evonik has launched four new AEROSIL fumed silicas that are easier to disperse, including AEROSIL E 972, AEROSIL E 805, AEROSIL E 812 and AEROSIL E 9200, which can help formulators save time and waste when developing coatings or paint formulations. Time-consuming and expensive grinding steps (e.g. using a bead mill).

Like other standard AEROSIL products, these four new easily dispersible (E2D) products can be used in paint and varnish formulations to provide controlled rheology and scratch resistance. Among them, E 972 is a more general product, and E 805 is suitable for Two-component polyurethane and epoxy systems, E 812 performs better in two-component polyurethane systems, and E 9200 is mainly used to improve the scratch resistance of the coating.

Characteristics of easily dispersible fumed silica

- Same compatibility as conventional fumed silica

- Same rheological properties as traditional fumed silica

- Reduce production process/grinding process complexity

- It only needs high-speed dispersion to add and use (no bead milling or high-shear grinding required)

- Can be added later to adjust rheological properties

INTRODUCTION Easy to disperse product introduction

AEROSIL E 972

-

Broad range of rheology control agents (anti-settling, anti-sag)

-

Suitable for all coating systems

-

Varnish+Pigment

-

easiest to disperse

-

Can be used for water-based coatings

-

Excellent optical properties (gloss, haze)

-

Treatment with dimethyldichlorosilane

-

(DDS) fumed silica

-

General industry, coil steel, powder, automotive paint, woodware, plastic paint

-

AEROSIL E 812

-

Automotive high-gloss acrylic varnish

-

Excellent transparency

-

Best performance among anti-corrosion primers

-

Excellent rheological properties - especially epoxy two-component systems

-

Very high efficiency

-

Fumed silica treated with octyltrimethoxysilane (OCTMO)

-

High compatibility

-

Mainly used in solvent-based systems

-

Automotive paint, marine & anti-corrosion general industry

AEROSIL E 805

-

Automotive high-gloss acrylic varnish

-

Excellent transparency

-

Best performance among anti-corrosion primers

-

Excellent rheological properties - especially epoxy two-component systems

-

Very high efficiency

-

Fumed silica treated with octyltrimethoxysilane (OCTMO)

-

High compatibility

-

Mainly used in solvent-based systems

-

Automotive paint, marine & anti-corrosion general industry

AEROSIL E 9200

-

Improved wear and scratch resistance

-

No typical rheological properties

-

Solvent based varnish

-

High addition amounts are possible

-

Low thickening

-

Mainly used in solvent-based systems

-

Easier to add than AEROSIL R 9200

-

Automotive paint, general industrial paint, plastic paint, powder coating, wood paint

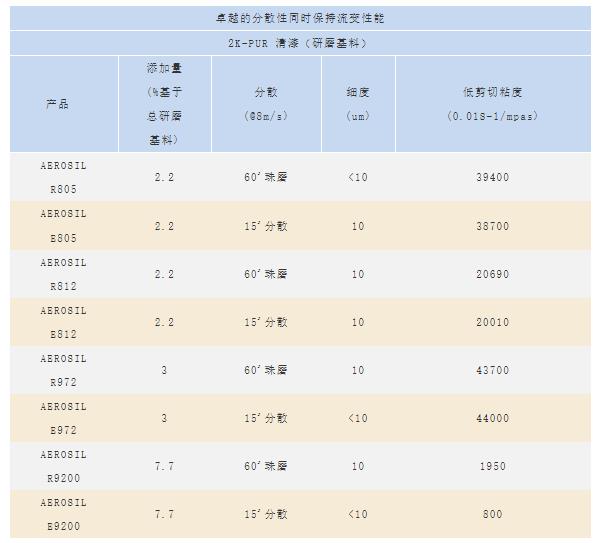

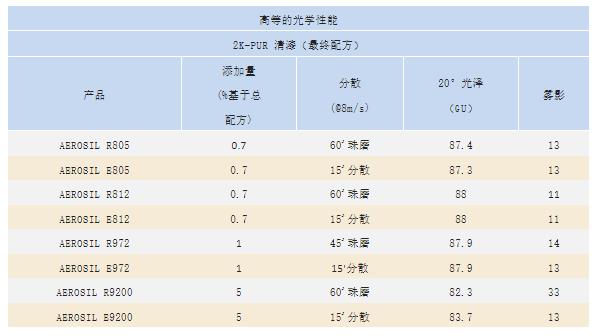

*Experimental data comes from Evonik laboratory

1. Can traditional type and easy-to-disperse E972 be replaced in a 1:1 ratio?

Absolutely, the easily dispersible type will not lose rheological properties under low shear.

2. Can E972 be added at the final dispersion and paint mixing stage?

Yes, it can be used as a rheology additive to adjust the final viscosity.