The role of TUBALL single-walled carbon nanotubes in reducing impedance in lithium batteries

Release Time:

2021-09-15

International company headquartered in Luxembourg Global specialist single wall carbon nanotube manufacturer.

With scalable technology capable of synthesizing single-walled carbon nanotubes at an industrial scale, OCSiAl produces high-purity single-walled carbon nanotubes under the TUBALL™ brand name with a current production capacity of 90 tons per year. In the first half of 2023, OCSiAl's single-walled carbon nanotube synthesis facility in Belgrade, Serbia, will be officially put into production, with a planned annual production capacity of 40 tons. In 2025, OCSiAl’s single-walled carbon nanotube synthesis facility in Luxembourg will also be put into production.

As an agent of OCSIAL, Shanghai Haiyi Technology and Trade Co., Ltd. has established a slurry production factory in China, Haiyi single-wall carbon tube slurry factory, and localized production to provide rapid product supply services for battery companies, greatly reducing the use of battery companies. cost.

Haiyi single wall carbon tube slurry factory address : Huzhou, China

Existing production capacity:

Water-based slurry: 4000 tons/year

Oily slurry: 1000 tons/year

Expansion plan: 2024: 20,000 tons/year

TUBALL

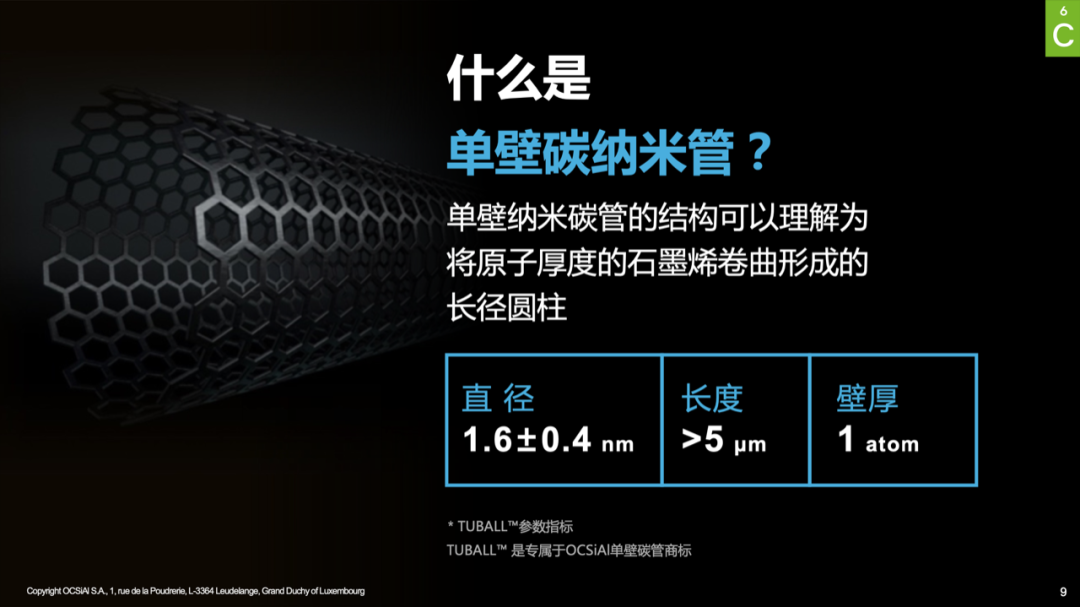

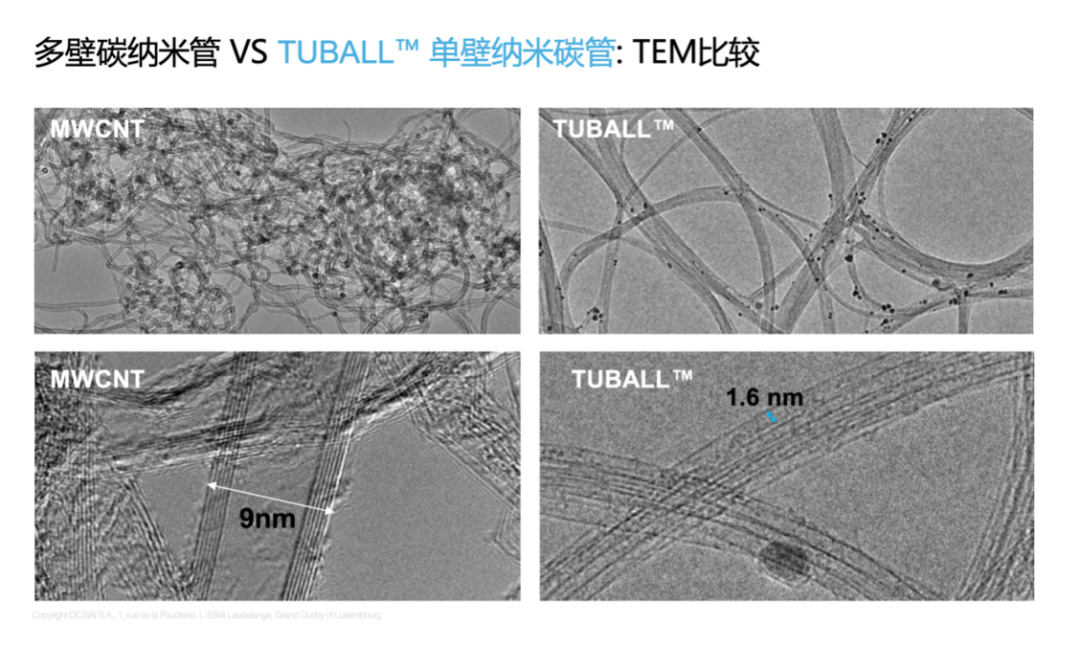

With special properties such as high electrical conductivity, high thermal conductivity, high strength and high flexibility – these outstanding properties of single-walled carbon nanotubes can effectively reduce the resistance of lithium-ion batteries.

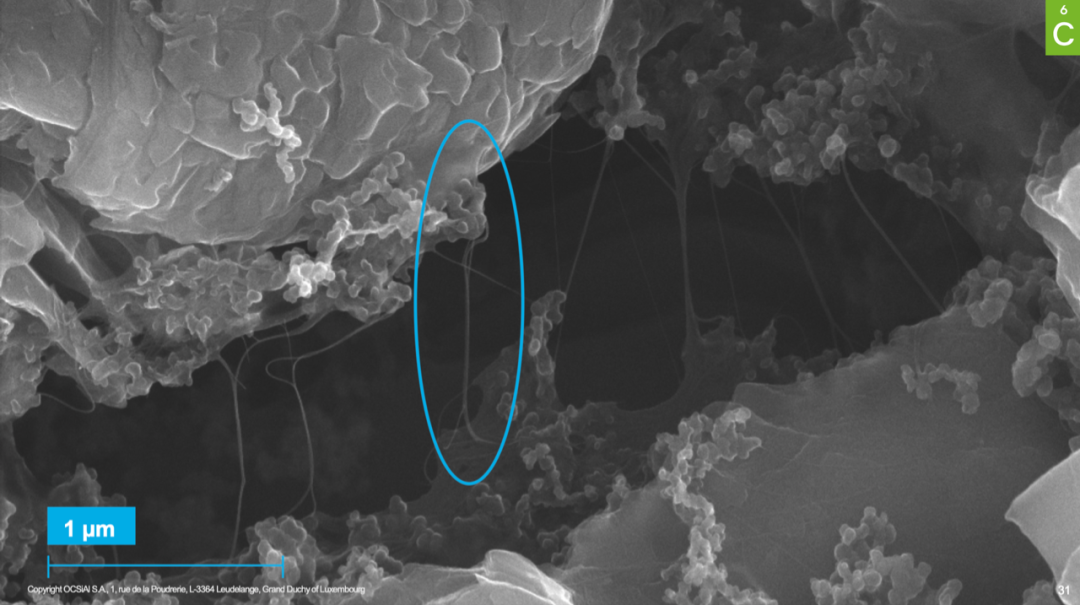

When added to lithium battery materials, single-walled carbon nanotubes form a three-dimensionally enhanced conductive network of connections.

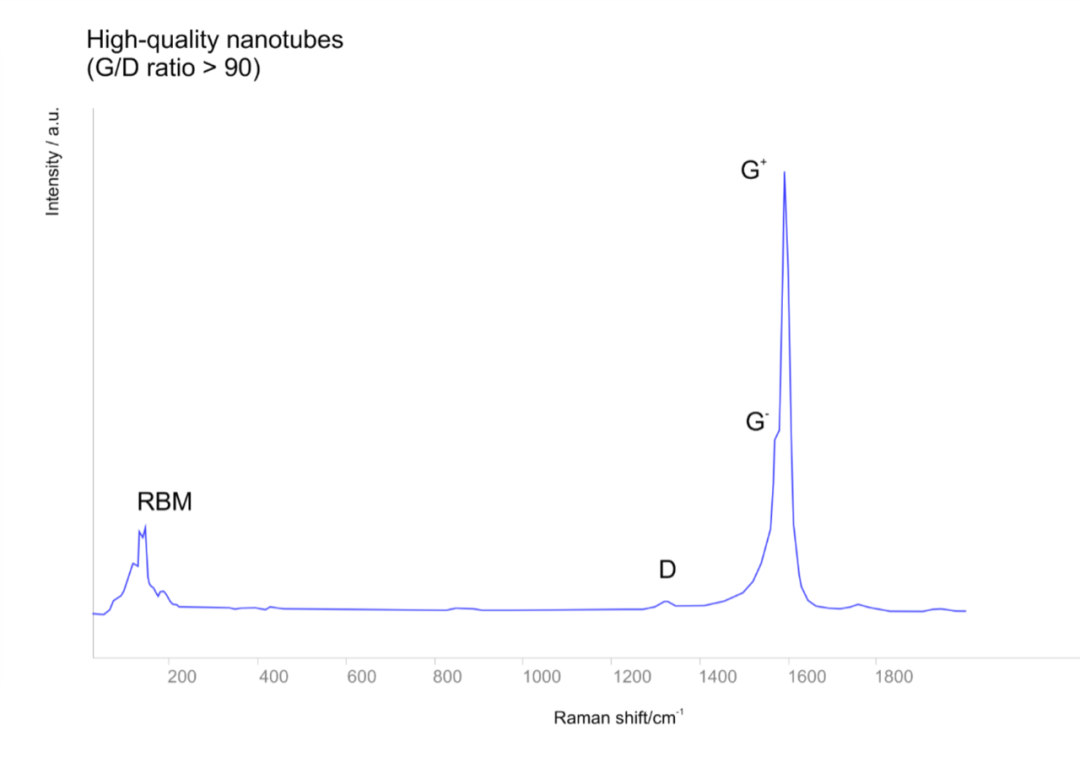

Raman spectroscopy detection provides single-walled carbon nanotubes in

In terms of quality characterization, the G/D ratio is an important indicator that accurately reflects the quality of carbon tubes. The G/D ratio of TUBALL single-walled carbon nanotubes produced by OCSiAl is >90. Compared with the conductive agents for lithium batteries on the market, TUBALL’s G /D ratio is the highest.

OCSiAl simplifies the processing of single-walled carbon nanotubes, advances the transformation process of single-walled carbon nanotubes from laboratory to industrial-scale materials, and develops conductive slurry TUBALL BATT for lithium-ion batteries.

For the application of positive and negative electrodes, there are currently two commercial products, TUBALL™ BATT, which are oil-based and water-based.

It is 0.4% single-walled carbon nanotubes and 2% PVDF

It is 0.4% single wall carbon nanotubes and 0.6% CMC

At the same time, regarding metal impurities, we use purified carbon tubes for both the positive and negative electrodes. At present, the metal impurities in the powder are <1%, and the metal impurities in the slurry are <40ppm, which can perfectly meet the needs of customers.

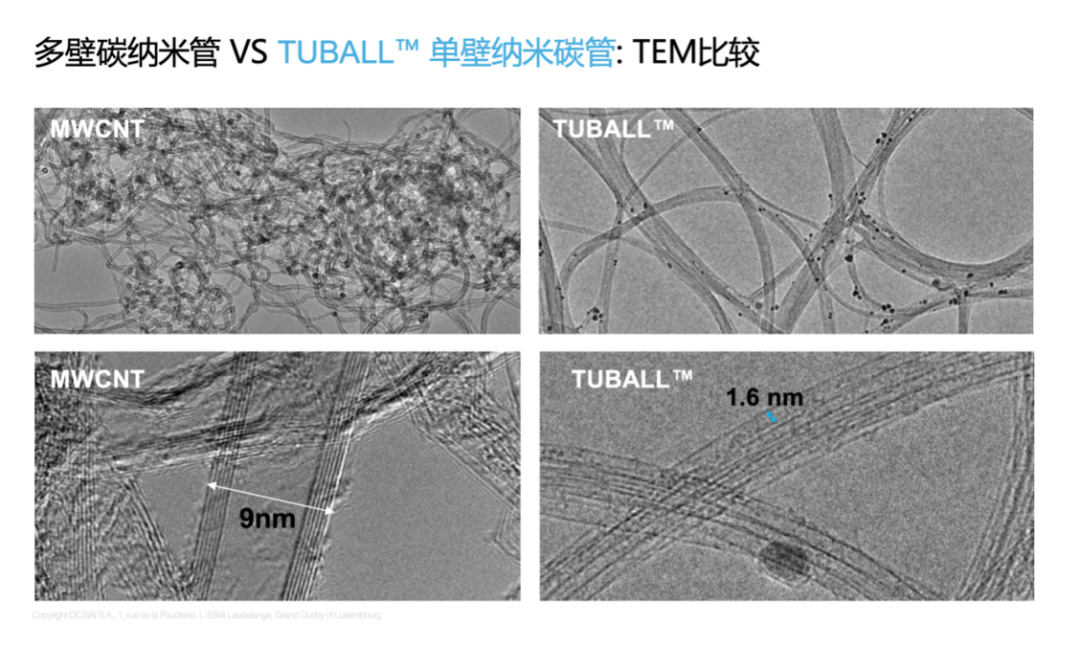

Due to their unique properties, single-walled carbon nanotubes outperform competitors and significantly improve the performance of lithium-ion batteries in terms of reduced resistance, energy density, adhesion and safety.

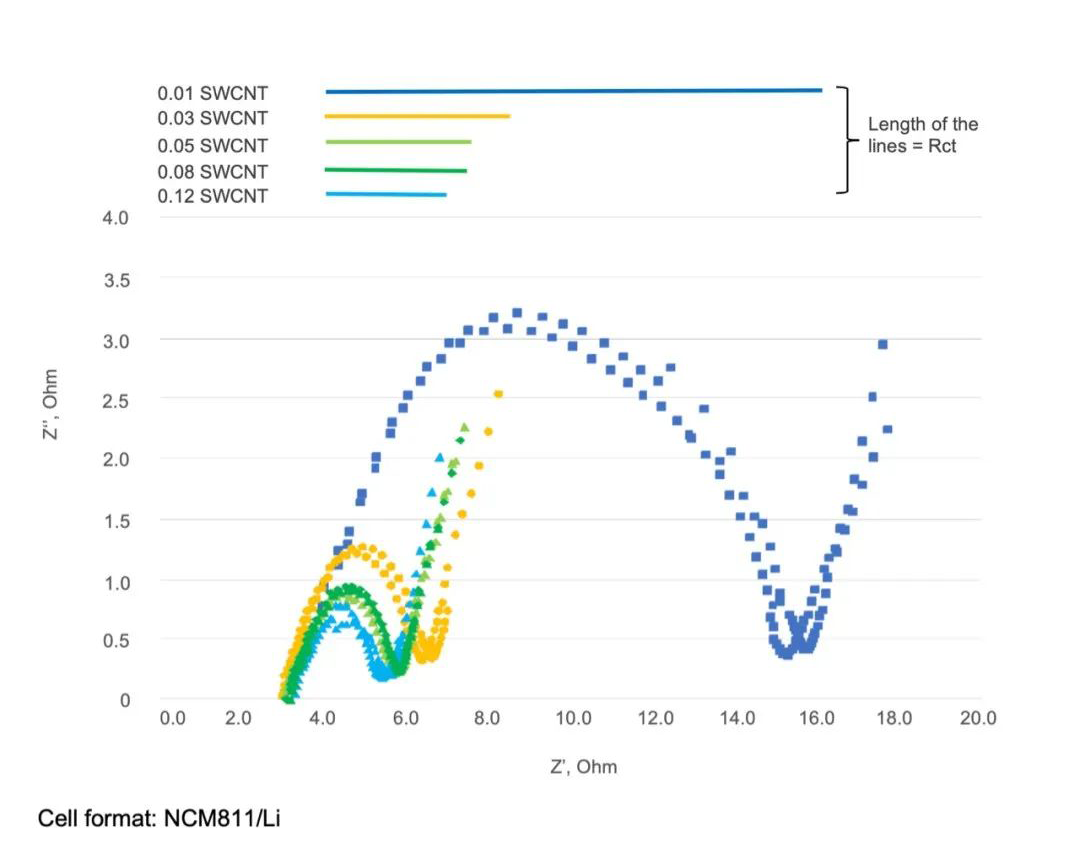

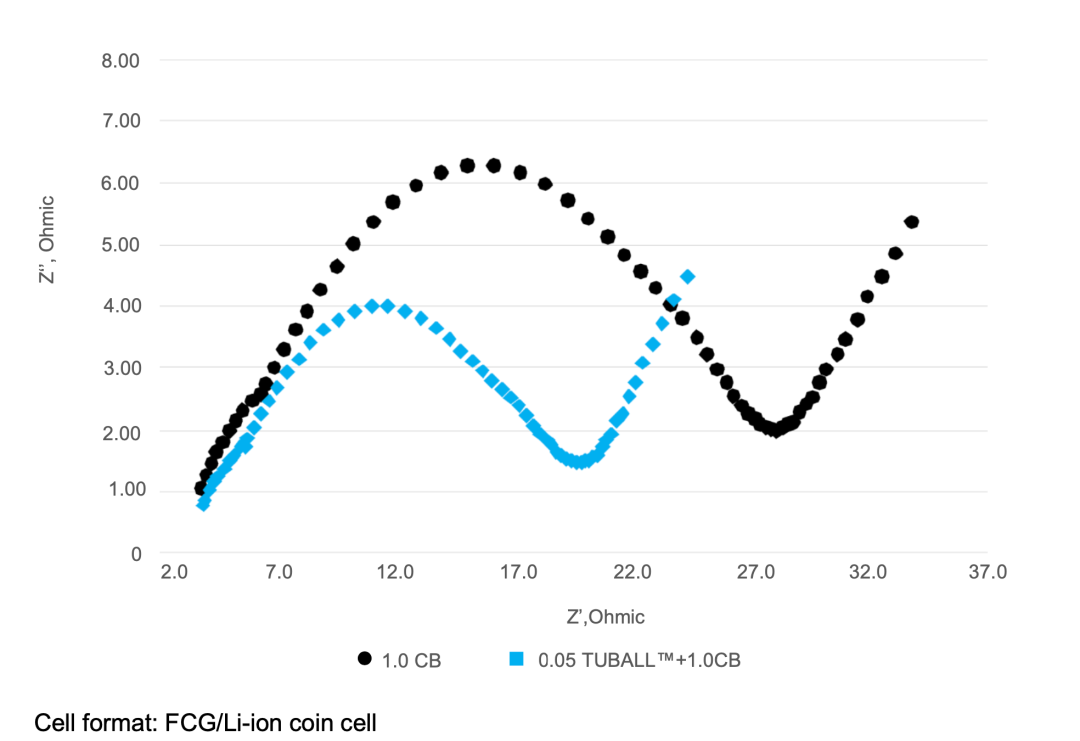

It is difficult to achieve this effect using traditional conductive cathode additives such as carbon black or multi-walled carbon nanotubes. Through electrochemical impedance spectroscopy, adding 0.05% TUBALL single-walled carbon nanotubes to the lithium battery formula significantly reduced the electrode polarization impedance.

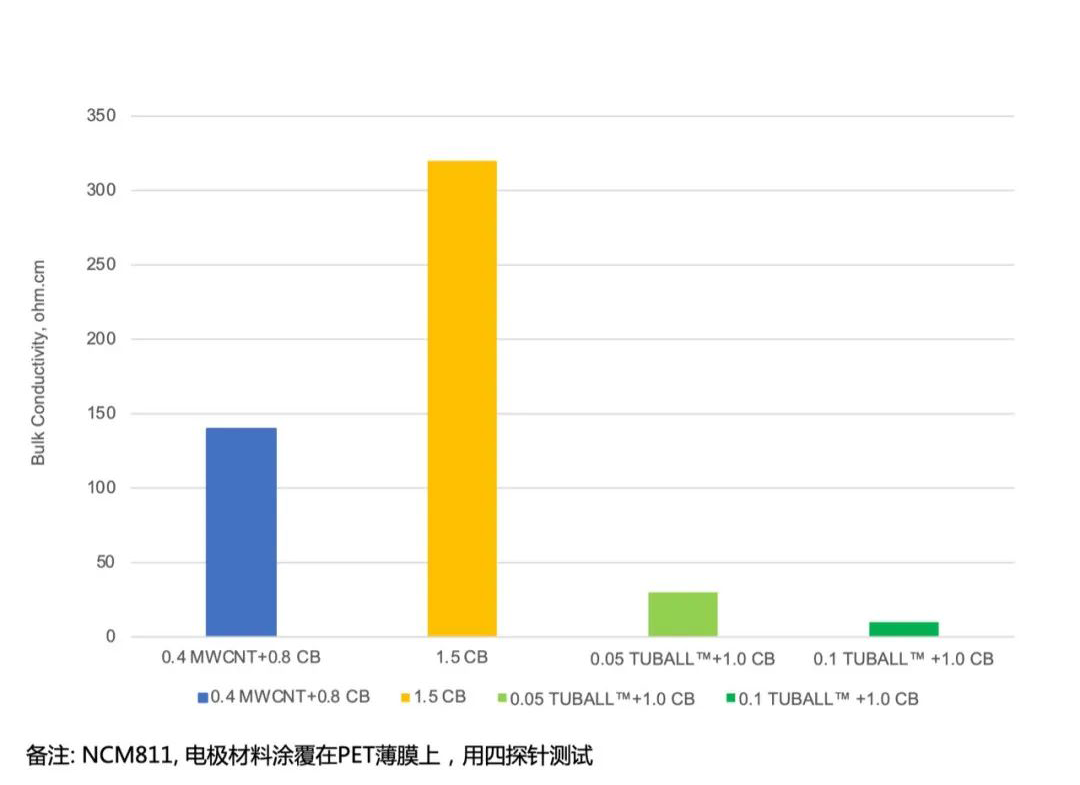

For example, comparing the internal resistance of different conductive additives in the NCM 811 formula shows that when TUBALL™ is added at 0.05%, the internal resistance of the pole piece drops by 70%, and when TUBALL™ is added at 0.1%, the internal resistance of the pole piece drops by 90%.

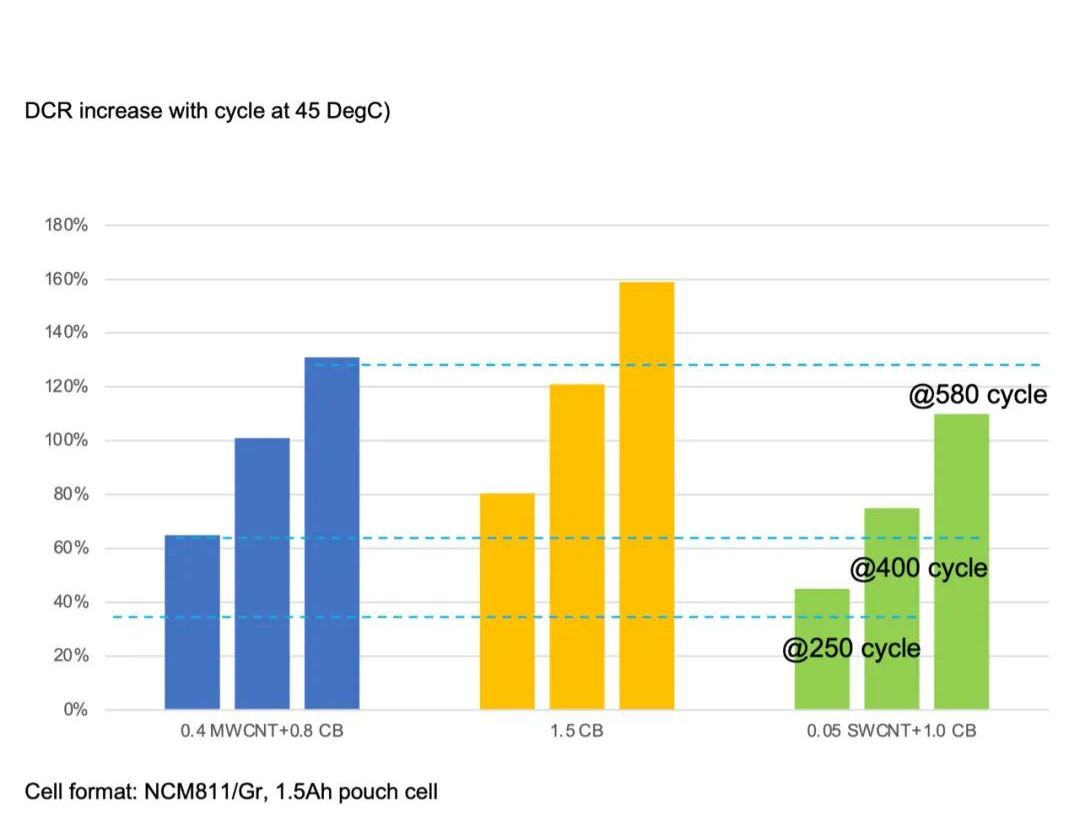

In a 1.5Ah NCM811/graphite pouch battery, 45°C cycle test data shows that adding single-walled carbon nanotubes can effectively inhibit DCR growth during cycling.

TUBALL single-walled carbon nanotubes coat the surface of silicon particles and establish highly conductive and durable connections between silicon particles. Through dense, long-range, conductive and strong connections, single-walled carbon nanotubes can maintain a durable conductive network channel even when the silicon anode particles expand in volume and develop cracks. This mechanism prevents premature failure of the negative electrode—single-walled carbon nanotubes help extend battery life to meet the stringent requirements of electric vehicle manufacturers.

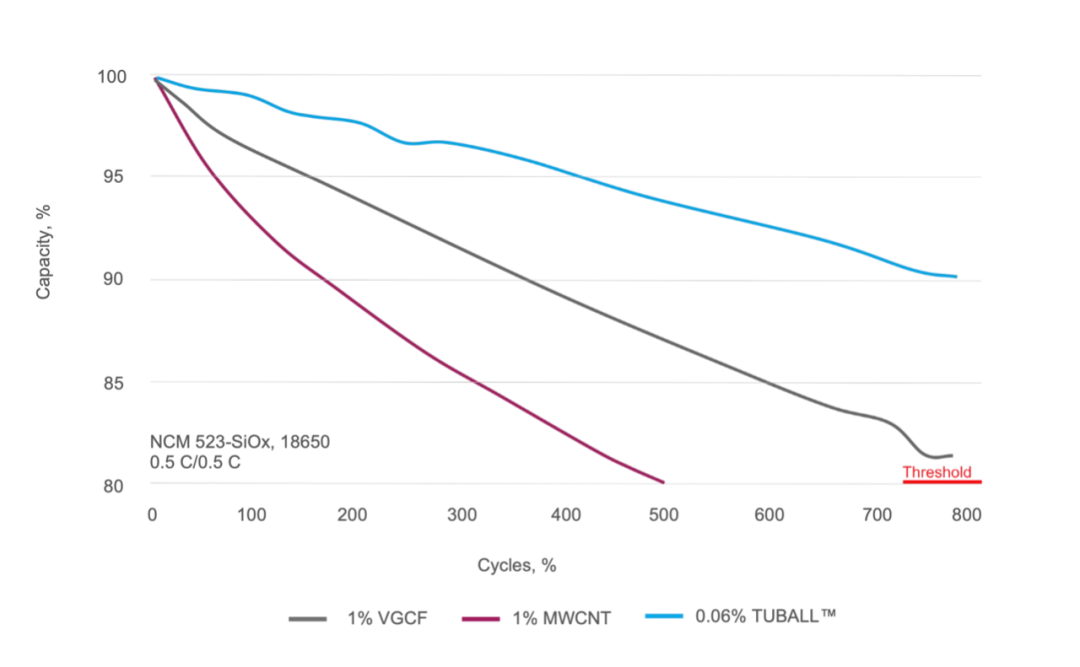

The application of TUBALL™ single-walled carbon nanotubes in silicon anodes is the best solution for high cycle life. The capacity retention rate of batteries added with single-walled carbon nanotubes remains above 90%, and after 1,000 cycles, it can still remain above 80%.

The electrochemical impedance spectrum in the graphite negative electrode shows that compared with 1% conductive carbon black, the conductive performance of TUBALL™ single-walled carbon nanotubes is also very superior.

In short, OCSiAl's single-walled carbon nanotubes can effectively reduce internal resistance and improve performance for cathode materials such as ternary and LCO, as well as silicon carbon and graphite anode materials.

-END-