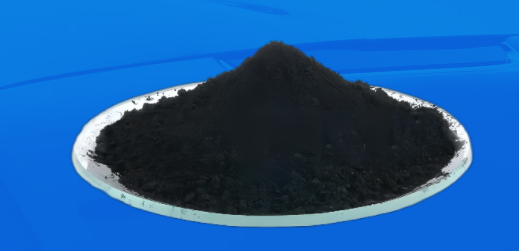

Pigment carbon black is used in industrial coatings

Release Time:

2021-09-15

Color black: Carbon black used as coloring pigment in inks, paints, coatings, plastics and other products. According to the blackness or coloring intensity and particle size, it is generally divided into four types: high pigment carbon black, medium pigment carbon black, ordinary pigment carbon black and low pigment carbon black. The main production processes of carbon black include channel method, furnace method and lamp method. Currently, high-pigment carbon black is mainly channel carbon black.

Carbon black characteristics : particle size, structure, surface treatment.

Particle size: The smaller the particle size, the better the blackness, the better the main color blue, and the longer the dispersion time and the greater the dispersion shear force.

Structure : Structure includes oil absorption value and specific surface area. The higher the structure, the higher the oil absorption value, and the larger the specific surface area; the more difficult it is for carbon black to disperse, and the higher the viscosity of the system.

Surface treatment: Surface treatment through quinone group or carboxyl group. The higher the degree of treatment, the better the stability of carbon black dispersion. The effect of viscosity is small, the dispersion stability is good, and the coloring power and brightness of carbon black are high.

Dispersant selection:

The original particle size of high-pigment carbon black is small, the structure is low, and the surface treatment is insufficient, resulting in a large amount of air in the gaps of the carbon black. It takes longer to wet, and it is necessary to choose a polymer containing pigment anchoring groups. used as a dispersant.

At the same time, it is necessary to use dispersion and stabilizing additives to prevent agglomeration and flocculation to achieve the best dispersion effect of carbon black, so as to achieve the best blackness and stability of carbon black.

Dispersion conditions and dispersion equipment:

Grinding slurry, pre-dispersion, wets the carbon black in the resin containing the dispersant. High shear grinding equipment is required to disperse the carbon black agglomerates. The dispersing equipment uses sand grinding, bead milling, ball milling, and three rollers. Grind grind.

Click to view large high-resolution image

High-pigment carbon black: TD890 and TD900 are successfully used in automotive paint, automotive repair paint, wheel paint, powder coatings, color pastes, etc., with the characteristics of high blackness, strong tinting power, and resistance to flocculation.

Medium and high pigment carbon black: TD888 is used in automotive interior plastic paint, wheel paint, and wood paint. It has the characteristics of high blackness, easy dispersion, and good stability.

Ordinary pigment carbon black: TD589P and TD588P are used in automobile bumpers, ordinary motorcycle paints, coil coatings, wood plastics, etc. They have the characteristics of good blackness, good blue phase, easy dispersion, and high cost performance.

TD890 is channel carbon black. The surface has undergone comprehensive oxidation treatment and is easy to combine with dispersants and resins. It exhibits high blackness and high tinting power. It has a smaller primary particle size and a lower oil absorption value, and is easier to disperse and will not flocculation.

Compared with similar products on the market, it has a better cost-effective advantage.

Does it meet the requirements for heavy metals and polycyclic aromatic hydrocarbons?

At present, ordinary pigments, medium pigments, and high pigment carbon blacks all meet the requirements for heavy metals and polycyclic aromatic hydrocarbons, and have relevant SGS certification reports.