Products | Application of new synthetic "spherical sand" in UHPC

Release Time:

2021-09-15

Application of new synthetic "ball sand" in UHPC

1. Introduction to ultra-high performance concrete

Ultra-high performance concrete (UHPC for short) refers to the general term for cement-based composite materials with a compressive strength of more than 150MPa, ultra-high toughness, and ultra-long durability, including ultra-high performance fiber-reinforced concrete (UHPC) UHPFRC), reactive powder concrete (RPC), ultra-high performance fiber reinforced cementitious composite (UHPFRCC), etc.

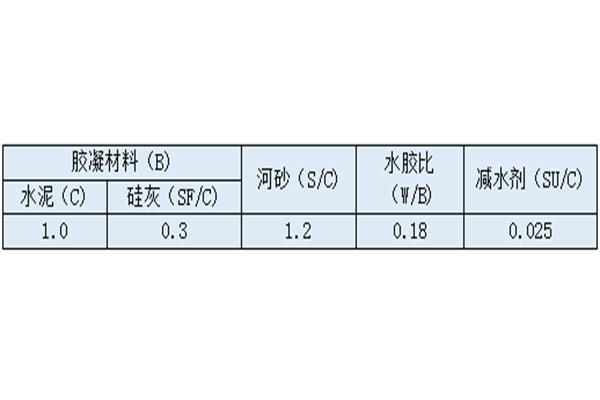

2. Base mix ratio

3. Preparation and maintenance of specimens

Specimen preparation method and maintenance system: Stir the dry mixture except fiber for 5 minutes, add water and high-efficiency superplasticizer mixture and stir until a slurry is formed, gradually add steel fibers through the screening method, stir for 5 minutes after addition, and discharge the material into the mold. ; Normal temperature curing 8h-12h demoulding, 90℃ steam curing 72h, normal temperature curing to 28d test.

ENTER TITLE

4. Introduction to special aggregate molding sand

Sunshine molding sand (HYTIDE SF series) is made from a variety of raw materials and screened through special processes such as mixing, refining, and granulation. Its dense crystalline structure ensures high hardness and strength, perfect spherical shape, and glass body surface. its application fields.

Meet the Jiangsu Provincial Engineering Quality Inspection Center-"Construction Sand" standards

Supply grade:

HYTIDE SF005, mesh number: 40-140 mesh;

HYTIDE SF520, mesh size, 8-40 mesh;

Typical data:

Fineness modulus: 2.5;

The total crushing value index of artificial sand: 12.2%;

Radioactivity: Internal/external exposure index is 0.1;

Alkali silicic acid reactivity (14d expansion rate): 0.07%;

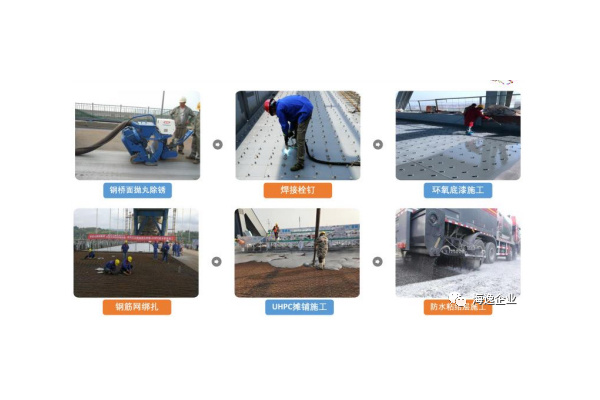

5. Application and construction

At present, the most mature application of UHPC is steel bridge pavement. The steel-UHPC composite bridge deck greatly improves the bridge deck stiffness and effectively solves the problem of "steel bridge deck pavement damage" and "steel structure fatigue cracking" - two major steel bridges. Typical projects: 21,000 square meters of pavement for the Yellow River Bridge on Fenghuang Road in Jinan (2021-8 Wuhan Port New Material Construction of CCCC Second Harbor Engineering Company), 48 days for paving of the Dongting Lake Bridge (suspension bridge) on the Hangrui Expressway in 2017 UHPC (STC) 65000 ㎡ (Hunan Middle Road Huacheng/Guangdong Guansheng Civil Engineering Construction).

6. Questions and Answers

1. What is the particle size range of sunshine type sand? Water absorption index?

Sunshine type sand has a particle size of 8-140 mesh (excluding powder) and can be screened into two specifications: SF520 (8-40 mesh) and SF005 (40-140 mesh). The water absorption rate is <0.5%;

2. What are the advantages of sunlight molding sand in UHPC?

A. Sunshine molding sand is a regular spherical shape, with a water absorption rate of less than 0.5% and no powder. It can reduce the water-binder ratio of UHPC, increase strength, and at the same time increase UHPC fluidity and improve pumping performance;

B. Due to the lower water-cement ratio, the concrete is denser, which improves the durability of UHPC;

3. What is the bulk density of sunshine molding sand? How much is used in UHPC?

Sunshine molding sand SF005 has a bulk density of 2200KG/m³, and SF520 has a bulk density of 2100KG/m³. In UHPC, it is recommended to use SF005 molding sand first, and the dosage is 30-50% of the total sand. The sand dosage can also be adjusted appropriately according to the concrete bulk density;

4. Is the sunlight molding sand stable in concrete?

A. Pressure steaming powdering rate test: steaming under 215℃ and 2.0MPa for 48h, the powdering rate is 1.86%, which is better than the standard (the standard is <5.9%, steaming for 3h);

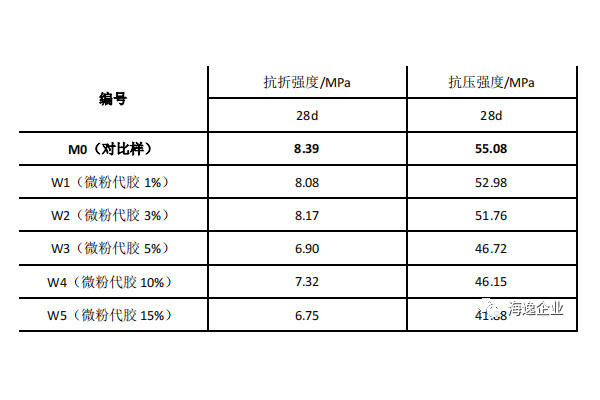

B. Micropowder glue substitute strength test. By increasing the proportion of cement substituted by micropowder, the flexural and compressive strength dropped sharply. The side reaction showed that the spherical aggregate is inactive and has strong stability;

C. Strong alkali stimulation: Soak the molding sand powder in 10% NaOH aqueous solution for 72H without hardening;

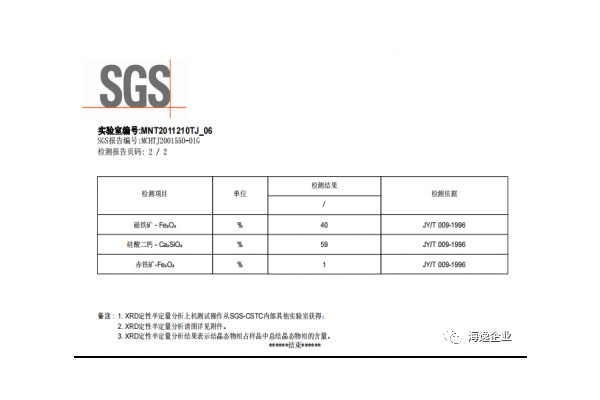

D. SGS test report: magnetite: 40%, dicalcium silicate: 59%, hematite: 1%; a complex of calcium silicate and calcium ferrite is generated during the high-temperature smelting process.