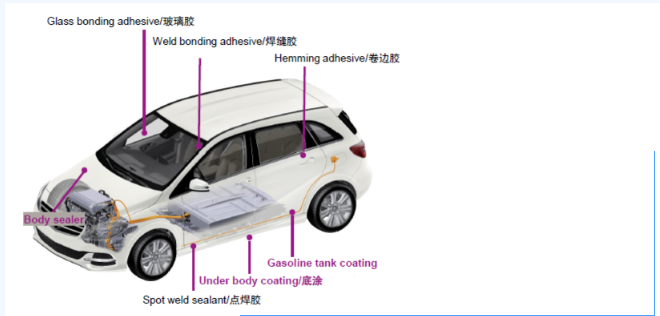

Application of Evonik's NOURYBOND series of tackifiers in automotive PVC plastisol

Release Time:

2021-09-15

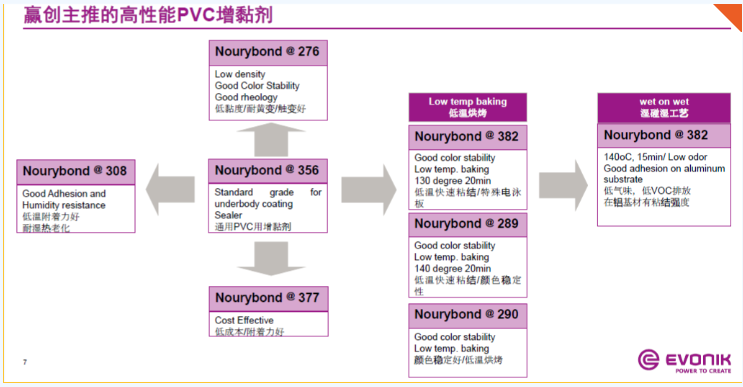

Evonik is a world-leading specialty chemicals company. With operations in more than 100 countries and regions around the world, in fiscal year 2021, Evonik generated sales of approximately 15 billion euros, and operating profit (adjusted EBITDA) reached 2.38 billion euros. Evonik is transcending chemical boundaries to provide customers with innovative, growth-promoting and sustainable solutions. NOURYBOND series products are tackifier products of Evonik's cross-linking agent department. They are mainly used in PVC plastisol to improve adhesion.

Industry issues

Product number

Product Features

2. NOURYBOND®382 has low odor, low viscosity, and no VOC; no intermediate coating process is required, and the baking temperature is shortened. It can meet customer requirements in 15 minutes at 140°C; especially for improving the adhesion of electrophoretic paint surfaces that are difficult to bond on the market. obvious;

3. NOURYBOND®276 has low viscosity, resistance to yellowing, and excellent thixotropic properties;

4. Use NOURYBOND®? Mysterious new product will be released soon, stay tuned!

Where do such products come from?

Some of these products are produced domestically, such as NOURYBOND®377, etc.

What are the domestic application cases of such products?

Most domestic models that use PVC plastisol use Evonik's tackifier products;

Are these the only products currently recommended by Evonik? Are there any new products?

Evonik NOURYBOND's newly developed tackifier product is expected to be officially promoted to domestic customers on a large scale in the fourth quarter of this year. The new product will help customers in the PVC plastisol industry solve the bonding problem of aluminum plates without electrophoresis treatment, so stay tuned!

Note: Polyvinyl chloride (PVC) plastisol has been widely used in the automotive industry. It is mainly used in the welds or overlaps of electrophoretic paint steel plates on automobile bodies, as well as in the underbody, wheel covers and lower skirts. Its typical products It is PVC stone-resistant car bottom coating and PVC weld sealant. Its functions are stone-hit resistance, sealing, and sound insulation and noise prevention. The usual PVC plastisol construction process is: sequentially process the inner sealant, hem glue, roof groove glue, bottom sealant and bottom coating glue, and then enter the drying room to bake to plasticize it; then apply it on the surface of the car body Spray midcoat, color paint, and finally varnish in sequence.