Application of Evonik matting powder in ink industry

Release Time:

2021-09-15

Evonik Matting Powder Application in ink industry

Reduce the gloss of the coating film and obtain a matting effect What is matting powder?

Matting powder is also known as matting agent. Common matting powder is a chemical substance that is easily dispersed and organically processed. The main purpose of matting powder is to reduce the gloss of the coating film and obtain a matting effect. Common matting powder types include: metal soap, wax powder, silica, functional fine materials, low molecular thermoplastic resin, etc. Evonik matting powders are all silica and appear as white dispersed powder or granules. By controlling its particle size, particle size distribution and surface properties, Degussa matting powders can provide excellent matte effects to printing inks.

Evonik’s special synthesis process gives its matting powder the following characteristics:

PART. 0 1

Narrow particle size distribution, excellent matting effect.

PART. 0 2

High transparency, not easy to form haze. Because its refractive index is very close to that of most resins, its transparency is very good.

PART. 0 3

The film-forming surface feels excellent, smooth, scratch-resistant, and wear-resistant.

PART. 0 4

Strong stability under high shear.

PART. 0 5

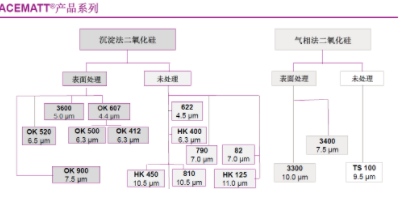

It has no effect on ink drying and recoating adhesion. Introduction to Evonik’s matting powder product series There are two synthesis methods for Evonik matting powder, namely precipitation method and gas phase method. On this basis, we can also perform various surface treatments on silica to obtain unique matting powder products.

Matting powder FAQs

Q: Does Evonik matting powder need to be ground? No, matting powder is a material added later. It only needs to be dispersed at high speed to achieve matting effect. If it is ground, it will destroy the particle size and surface treatment of the matting powder, affecting the matting efficiency.

Q: What is the difference between surface treatment and unsurface treatment?

Good transparency without surface treatment.

The surface of OK series is treatd with wax, which has good anti-settling effect and good hand feel. The surface of the 3000 series is treated with polydimethylsiloxane, which has good hand feel and good slipperiness.

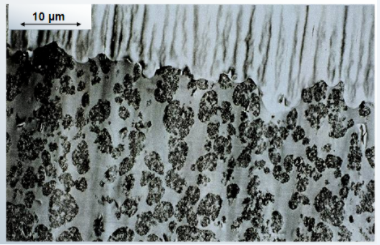

Question: Matting powder is not scratch-resistant. Is there any matting powder that is scratch-resistant?

Yes, the spherical silica under the Evonik product series can meet the requirements of scratch resistance. If you are interested in this type of product, you can contact Haiyi Enterprise for more information.