Honeywell HPL-6901 transparent engineering plastic lubrication solution

Release Time:

2021-09-15

Engineering plastics have excellent comprehensive properties, such as high rigidity, low creep, high mechanical strength, good heat resistance, and good electrical insulation. They can be used in harsh chemical and physical environments for a long time, and can even replace metals as engineering structures. Materials used.

Advantages of engineering plastics

Among the many performance advantages, transparency has become the advantage of engineering plastics to "break a new path and overtake in corners" and shine in some subdivided applications. PMMA and PC, as well-known transparent engineering plastics, not only have good optical properties, but also have light weight. It has the advantages of plastic properties such as impact resistance and easy processing and molding, so it can replace inorganic glass and is widely used in the optical field and other fields (electrical and electronics, automobiles, consumer goods, etc.).

Injection molding problems

However, as engineering plastics are used in more and more situations, the performance requirements for the materials themselves are getting higher and higher. In addition to the traditional high strength, high and low temperature impact resistance, anti-static, antibacterial, corrosion resistance, high heat resistance, etc. Requirements, processing continuity without affecting transparency has also become a major problem that plagues injection molding production, especially for continuous injection molding of products with multiple cavities in one mold and complex structures. Smooth demoulding results in long processing cycles and easy-to-use parts on the surface. Scratches or even breakage, blocked flow channels, etc.

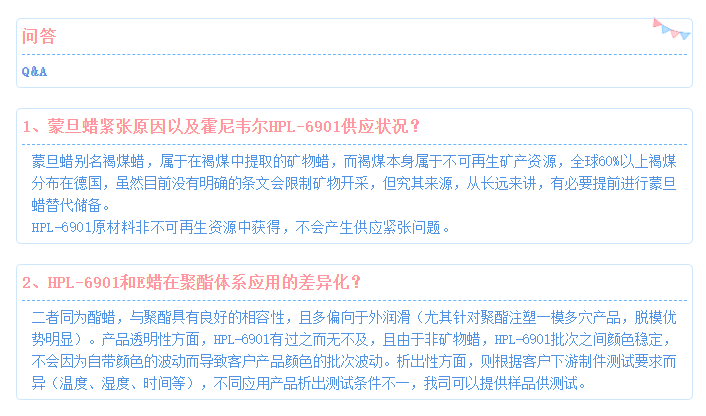

Montan wax

Montan wax has excellent temperature resistance and can match the polyester processing temperature without failure/precipitation. The polar segments and non-polar segments that exist at the same time can provide both internal and external lubrication and compatibility, so it is usually used as Continuous demoulding solution, however, since montan wax is a mineral non-renewable resource (derived from lignite), the resulting supply problems have forced customers to seek new alternatives.

Honeywell HPL-6901 Ester Wax

Honeywell HPL-6901 ester wax has excellent lubrication and temperature resistance, good compatibility with polyester, and is mostly used for external lubrication. It is especially suitable for the modification of transparent products such as PC and PMMA. The amount is 0.3-0.5%, which helps improve the demoulding performance while having little impact on the transparency of the product. It can help customers improve product processing efficiency and the appearance of the final product. Compared with the classic PETS (pentaerythritol stearate), it has a higher melting point. and back-end take-off features. For non-transparent areas, HPL-6901 can also be used as processing lubrication and demoulding, such as PC+GF, PC/ABS, PET+GF and other formula systems.

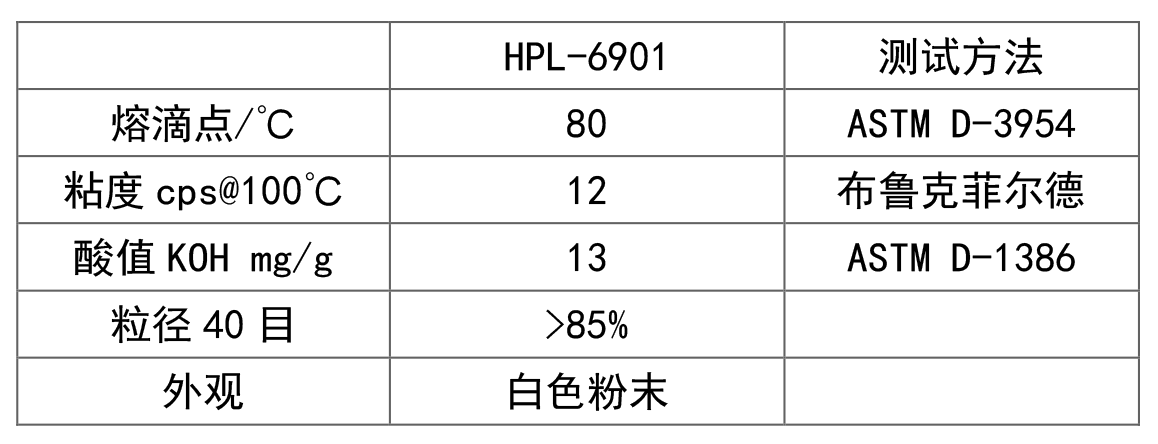

HPL-6901 typical parameters :

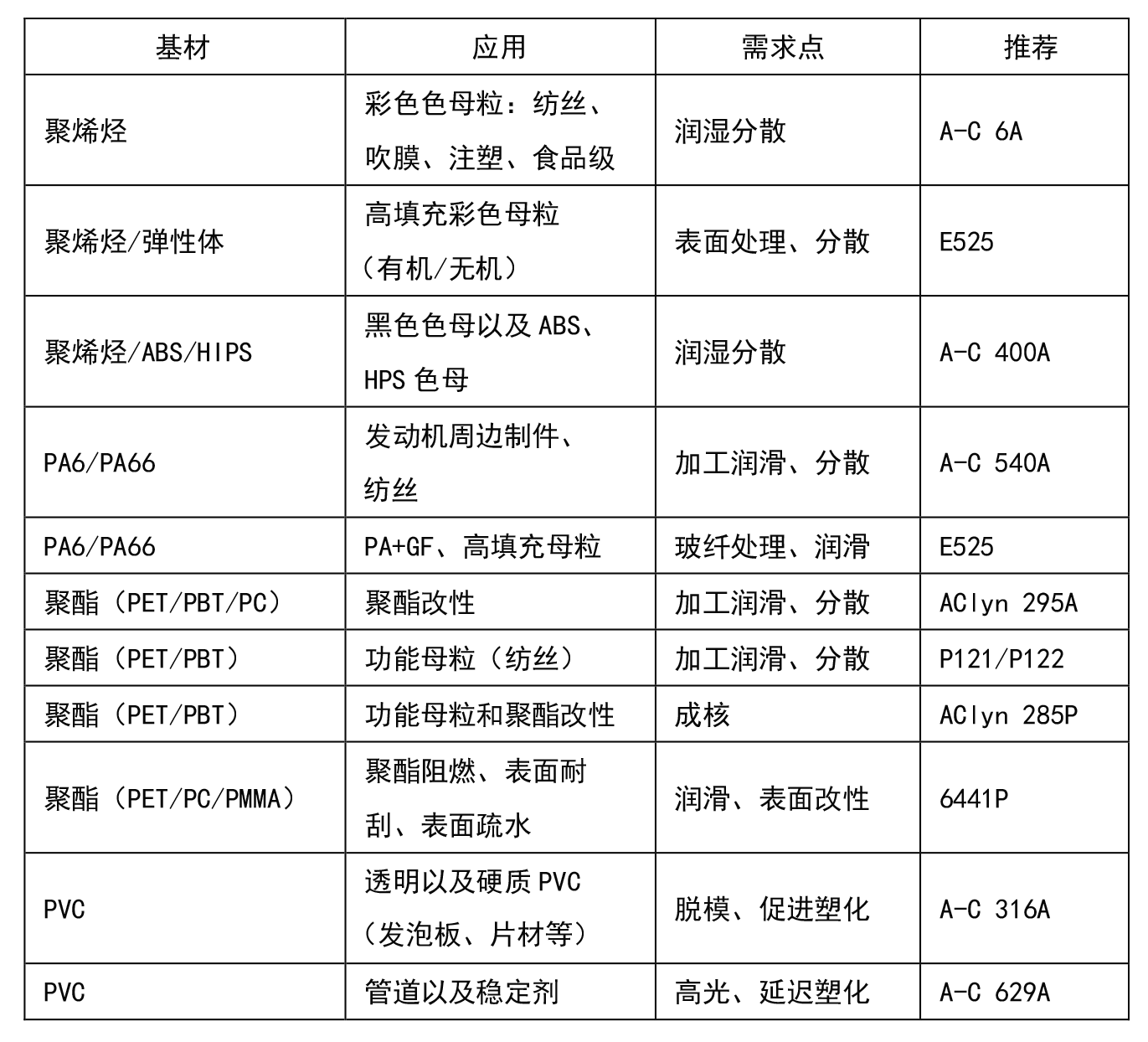

Haiyi plastic industry lubrication and dispersion solutions: