Products丨Torsa PANGEL is used in emulsified asphalt

Release Time:

2021-09-15

1. Introduction to emulsified asphalt

Emulsified asphalt refers to an oil-in-water (O/W) emulsion formed by heating and melting asphalt and dispersing fine particles in an aqueous solution containing emulsifiers and additives under the force of mechanical stirring. According to the different electrical properties of the emulsifier used, it is divided into cationic emulsified asphalt, anionic emulsified asphalt, nonionic emulsified asphalt, etc.

This article mainly introduces the application of PANGEL in anionic emulsified asphalt.

2. Introduction of Torsa PANGEL products

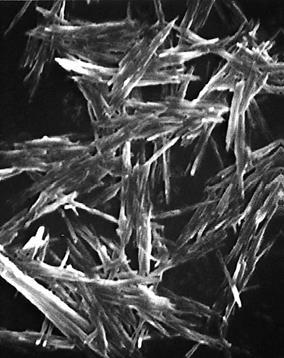

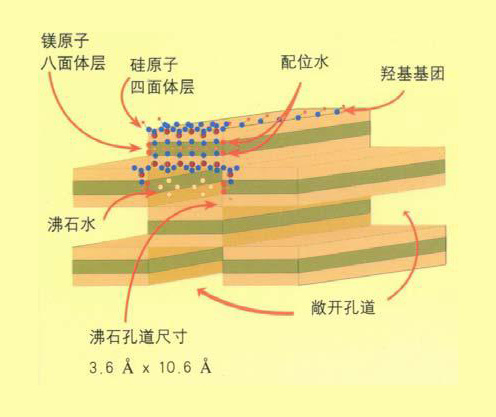

Torsa PANGEL is a hydrated magnesium silicate, belonging to the class of layered silicates. The structure of PANGEL is composed of two layers of tetrahedral silica units connected by a central oxygen atom and an octahedral layer of discontinuous magnesium atoms. This structure gives PANGEL particles a microfiber needle-like structure.

Torsa PANGEL features:

· Provides thixotropic properties, prevents settling, prevents sagging, and increases construction performance.

· The suspension is not affected by electrolysis and high temperature environments.

· Improves extremely high thixotropic performance while having a relatively small impact on viscosity.

3. Preparation of emulsified asphalt emulsion

1. Adjust the pH value of water, then add PANGEL while stirring (stir at 1000rpm for 5-10 minutes), fully disperse, add emulsifier to disperse evenly, then add a certain amount of dilution water to form an emulsion.

2. Melt the asphalt and dehydrate it in the range of 100-200℃ to become asphalt liquid.

3. Inject the emulsion into the mixing barrel of the mixer first, then slowly add the asphalt liquid into the barrel in a thin stream, stir for 2-3 minutes, then add 80-100°C hot water, stir for 6-8 minutes, and it is emulsified asphalt.

4. Advantages brought by using PANGEL

· A coating with a good surface finish can be obtained.

· Since it is very easy to disperse and suitable for inclusion in the system, and is compatible with other components of the system, no modifications to its manufacturing process are required.

· Better emulsions can be obtained by using colloid mills with tight single die sizes to distribute bitumen droplets.

· Improved the stability of the system and introduced rheology (thixotropy and pseudoplasticity).

· Improves the water resistance of emulsions and makes the system compatible with all types of water.

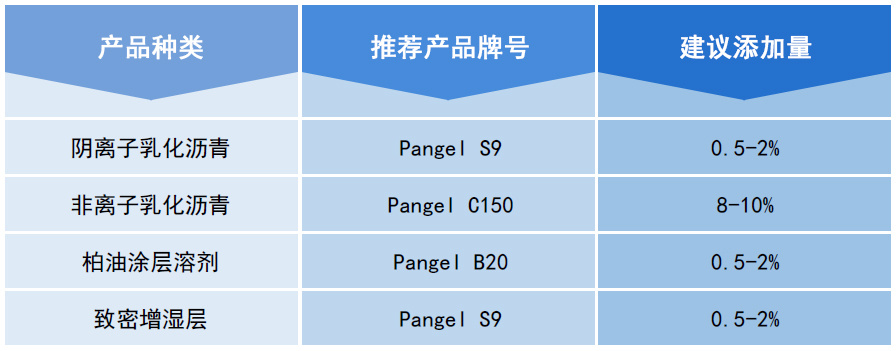

5. Product recommendation list