Product丨A new generation of photocatalyst additives: Archroma PERPRET® AIR titanium dioxide microcapsules

Release Time:

2021-09-15

1. Traditional photocatalyst materials cannot be directly added to organic coating systems.

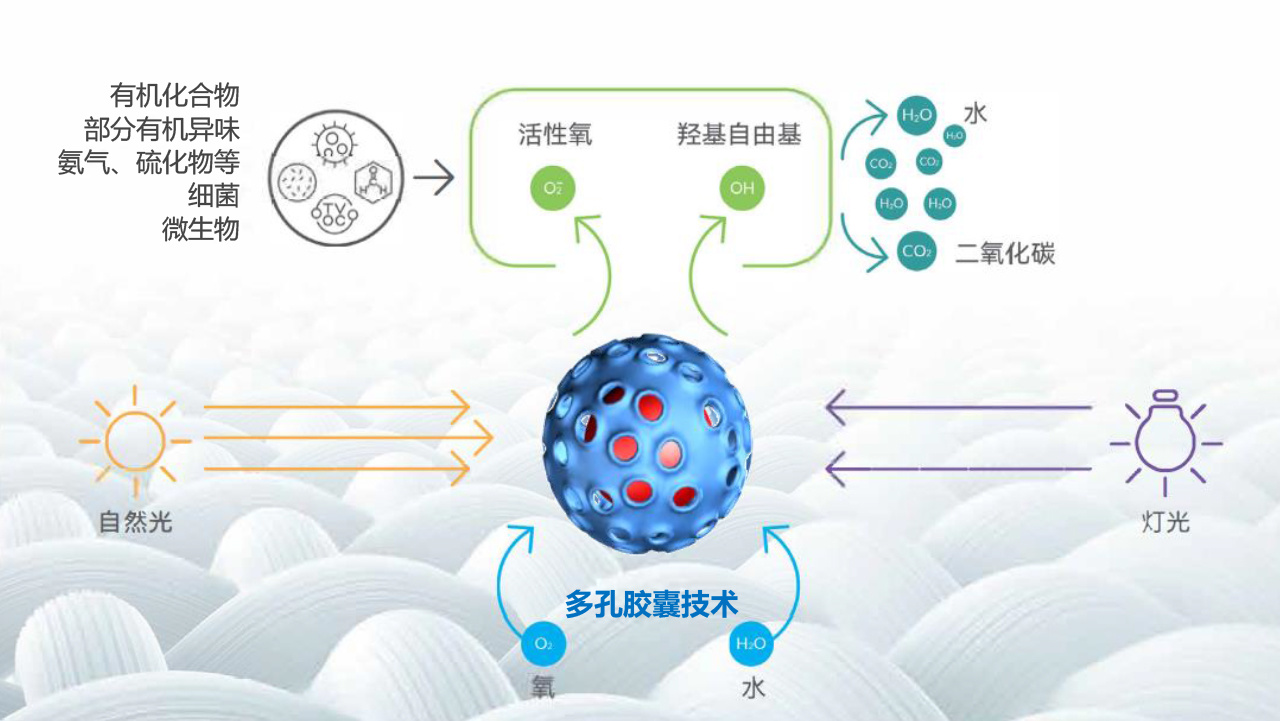

The photocatalyst reaction of titanium dioxide means that under light conditions, the hydroxide radicals and water molecules adsorbed on the surface of the material are oxidized into hydroxyl radicals with extremely strong oxidizing ability, and further decompose organic compounds and some inorganic substances with unstable chemical bonds. The process of eventually degrading it into small molecular substances such as water and carbon dioxide.

Photocatalyst technology was first discovered in the 1930s and has now been applied in many fields. Using nanoscale titanium dioxide as a photocatalyst is one of them. Due to its good photostability and high reactivity when reacting, nano-titanium dioxide is widely used in wastewater treatment, air purification, sterilization and disinfection and other fields.

On the other hand, due to the photocatalytic effect of titanium dioxide that can degrade organic matter, it cannot be directly added to organic coating formulations as a functional material. In fact, the titanium dioxide currently widely used in coatings uses various means to reduce or even eliminate the instability caused by its photocatalytic effect, such as selecting rutile titanium dioxide with a lower photocatalytic effect, and adding inorganic substances to its surface. Covering etc.

2. Product features of PERAPRET ® AIR

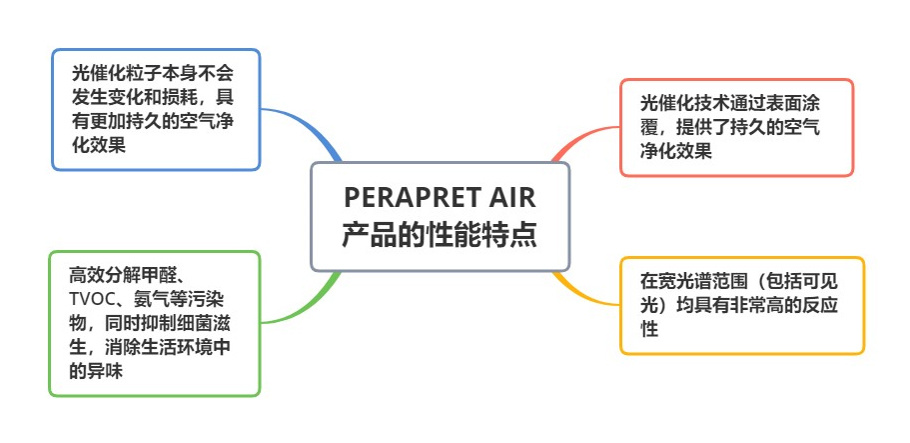

Archroma PERAPRET ® AIR ( hereinafter referred to as AIR) uses unique technology and production processes to coat titanium dioxide with photocatalytic effect in a porous microcapsule structure, effectively solving the problem that photocatalyst materials cannot be added to organic coatings difficult problem.

PERAPRET ® AIR products eliminate harmful substances through photocatalytic reactions and will not degrade the organic resin of the base material.

3. Application effect of PE RAPRET ® AIR products in coatings

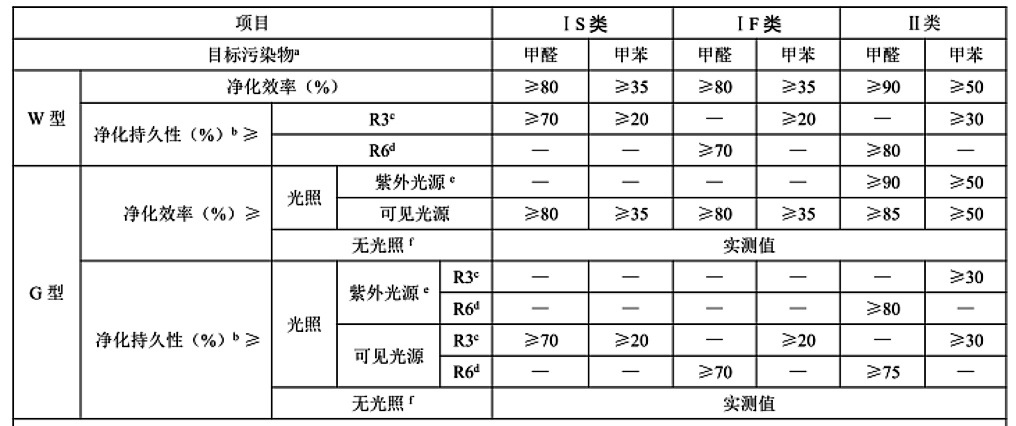

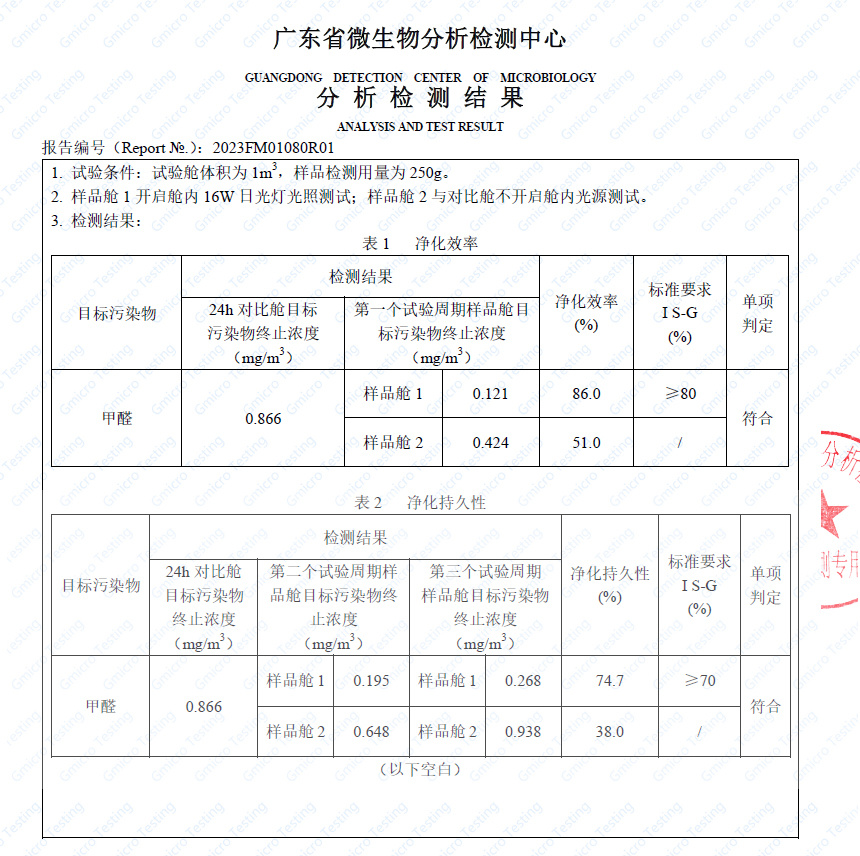

In order to verify the actual effect of AIR products after adding them to paint, we chose to add AIR products to the formula of an interior wall latex paint at a proportion of 0.5%. Testing by a third-party authoritative certification agency shows that the film-formed coating has ideal effects in terms of formaldehyde purification efficiency and purification durability. The testing method refers to the China Building Materials Association industry standard "JC/T 1074-2021 Purification Performance of Coating Materials with Indoor Air Purification Function". The 24-hour formaldehyde purification efficiency reaches 86%, and the three-cycle purification efficiency reaches 74.5%, which meets the certification standards for coating materials (IS type, G type) for interior decoration and photocatalytic air purification functions.

4. Recommended applications

According to the characteristics of AIR products, as a coating additive, it has good application prospects in various applications such as architectural coatings such as interior wall latex paint, exterior wall coatings, and industrial coatings such as coil coatings, curtain wall coatings, wood paints, and automotive interior paints. .