Products | Application of thixotropic agents in the ink industry

Release Time:

2023-11-14

What is thixotropy? What effect does thixotropy have on inks?

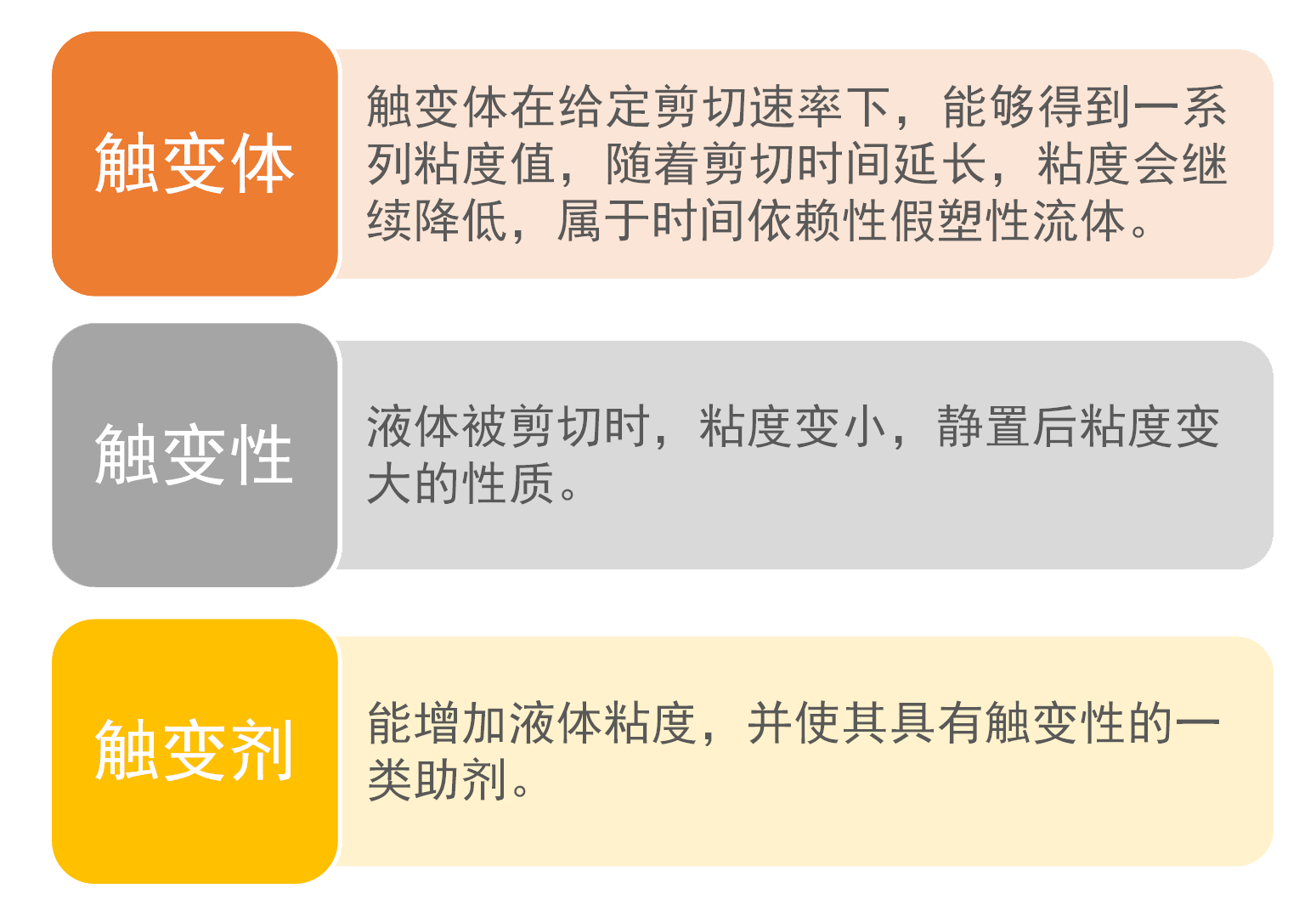

Thixotropy: refers to a "thixotropy" property in which the consistency of an object (such as paint, coating) becomes smaller when sheared, increases when shearing is stopped, or becomes larger when sheared, and becomes smaller again when shearing is stopped. "That is the nature of "change".

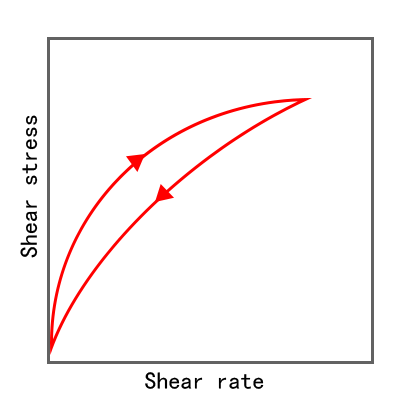

The larger the closed loop area is, the higher the thixotropy of the coating is.

If the hysteresis loop coincides with the original curve, it indicates that the coating is not thixotropic.

Ink will have different viscosity requirements at different stages during its actual survival and use.

During the storage process, the ink is required to have a high viscosity to prevent settling.

During the printing process, the ink is required to have low viscosity and be able to print quickly.

During the drying process, the ink is required to have a certain viscosity to prevent sagging and help leveling.

Therefore, thixotropy is an essential property for inks.

Haiyi Company’s solution for thixotropy?

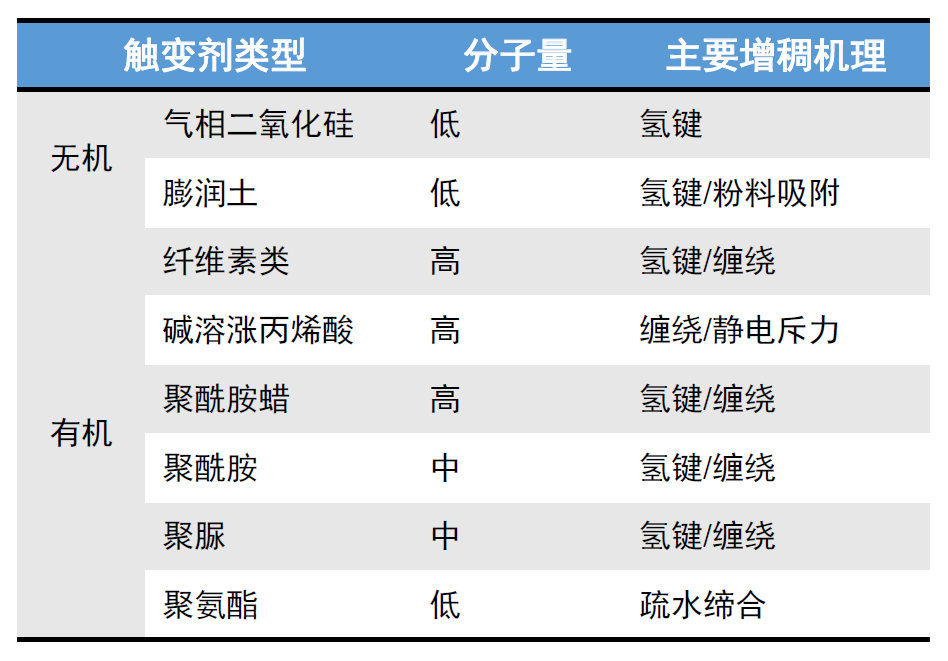

Common types of thixotropic agents used in inks are:

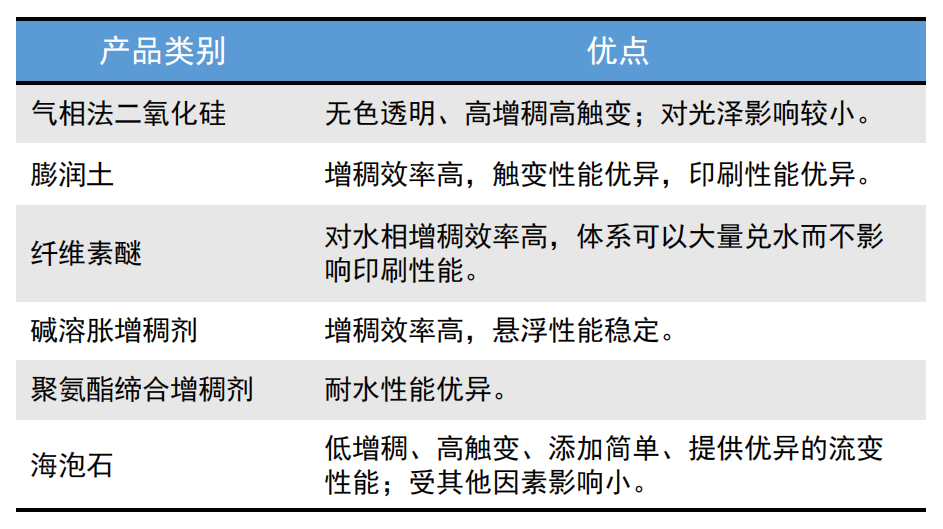

Different types of thixotropic agents have unique performance characteristics:

Different thixotropic agents have their own advantages and disadvantages. Our company has experience in using a variety of thixotropic agents. You are welcome to contact our sales staff to communicate and choose the product that is most suitable for your company!

Q & A

Q: If alcohol is added to the formula system, will it destroy the thixotropic effect?

Answer: In formula systems that require the addition of alcohol, our company recommends adding two types of thickeners: fumed silica and sepiolite. These two types of thixotropic agents have wide product adaptability and short onset time. After dilution with alcohol, thixotropic properties will be restored very quickly.

Recommended test A200 for fumed silica.

Meerschaum recommended test B42.

Question: Is grinding necessary to use gas silicon? Some products do not have a grinding process in the production process.

Answer: For conventional gas silicon to be effective, it must be ground to achieve the thixotropic effect. But our brand new brand E972 is an easy-to-disperse gas silicone that only needs to be dispersed at high speed! At the same time, it can bring the following properties to the ink: good anti-settling effect, especially suitable for various special pigments such as metal, pearlescent inorganic, etc. Can improve the water resistance of ink or light. It can increase the friction coefficient of ink or glossy surface, but has little effect on gloss.

Question: I have tested hydroxyethyl cellulose before, but it cannot be dissolved. Is there any recommended method?

Answer: The solubility of our product hydrophobically modified hydroxyethyl cellulose has been significantly improved compared to traditional hydroxyethyl cellulose. The specific dissolution method is as follows: First, the concentration of the mother liquor should not be higher than 2.5%-3%, otherwise the mother liquor will be difficult to operate. Second, the surface of NATROSOL (HMHEC) has been treated with hydration delay, which allows it to dissolve slowly instead of rapidly dissolving causing agglomeration and gelling. Therefore, adjusting the pH to a weak alkaline state can accelerate the dissolution of NATROSOL hydrophobically modified hydroxyethyl cellulose.

In addition, NATROSOL hydrophobically modified hydroxyethyl cellulose (HMHEC) can be added during the grinding and paint mixing stages. Adding it during the grinding stage can appropriately increase the viscosity of the grinding base material and improve grinding efficiency; adding it during the ink adjustment stage, it is recommended to add it in the form of an aqueous solution.