Product | Application of BYK clay additives in halogen-free flame retardant cables

Release Time:

2023-11-15

BYK-MAX CT 4260, a clay additive from BYK Chemicals, is used as a flame retardant synergist (anti-drip and char-forming additive), especially in halogen-free flame retardant wires and cables. It has excellent flame retardant synergy. On the basis of the flame retardant V0 test level, adding BYK-MAX CT 4260 helps wires and cables to reduce the overall usage of mineral-based flame retardants (ATH and MDH). The oxygen index is >36, and the tensile elongation is >250%. At the same time, the The tensile strength, volume resistivity, melt fluidity and water absorption of wires and cables have been significantly improved.

01 Basic features of BYK-MAX CT 4260 clay additive

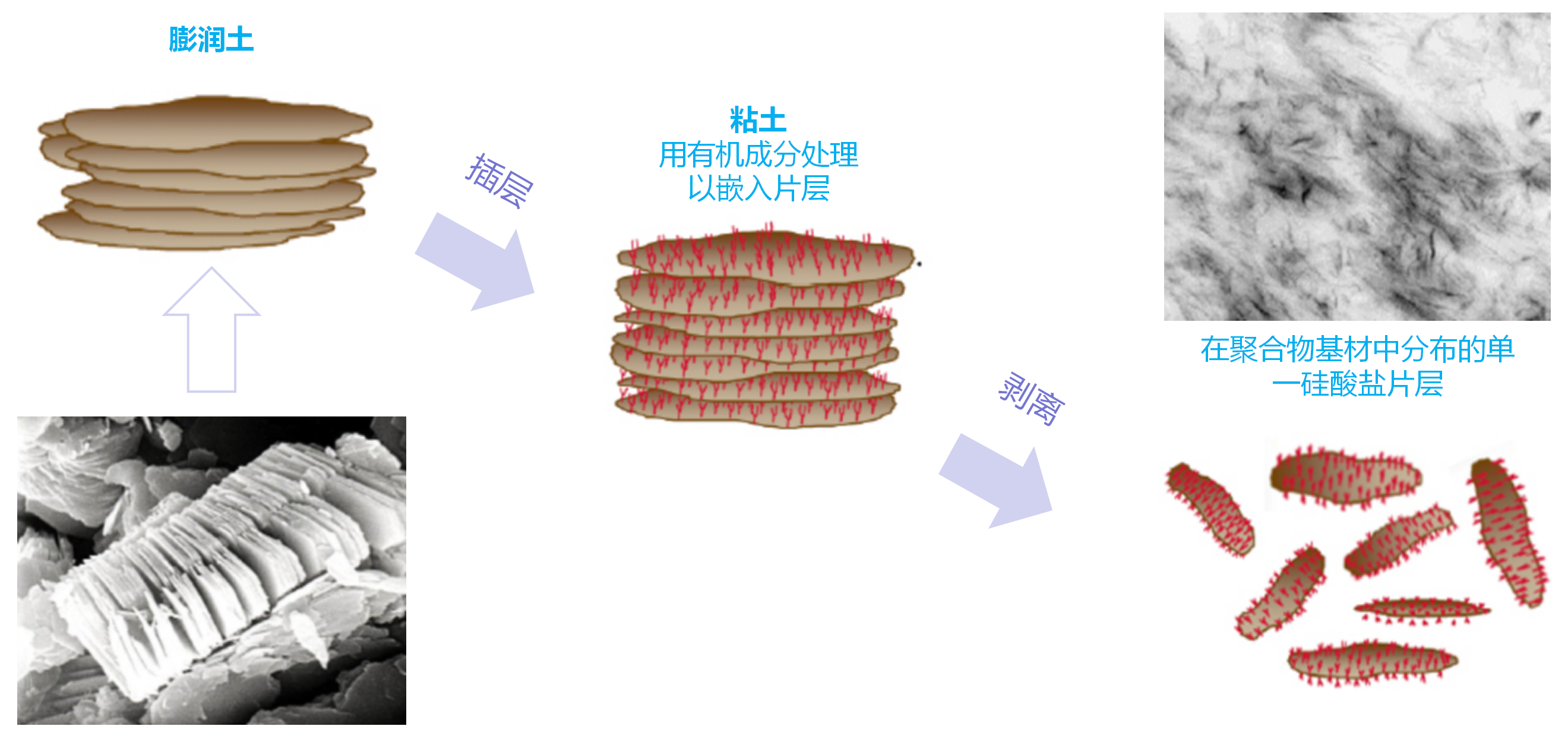

BYK-MAX CT 4260 is a surface-treated natural mineral product derived from bentonite (montmorillonite/smectite). Heterogeneous flake minerals (similar to talc/kaolin/mica): approx. 1 nm thick, diameter 300 – 1000 nm (DIN A4).

The clay additive BYK-MAX CT 4260 is produced through the use of a special organic intercalation and peeling process. Good peeling processing can contribute to excellent flame retardant properties and mechanical properties.

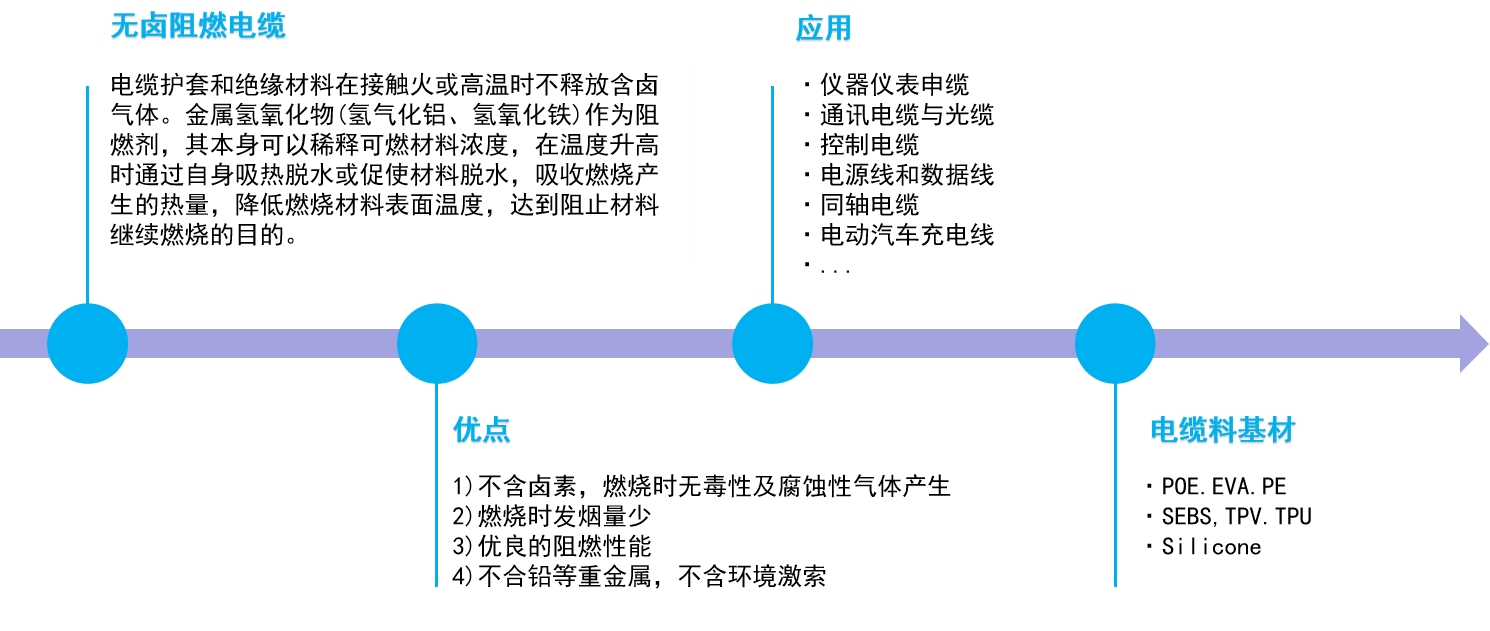

02Advantages and processing difficulties of low-smoke halogen-free flame-retardant wires and cables

Compared with traditional PVC or halogen-containing cable materials, halogen-free flame retardant (HFFR) cable materials have multiple advantages:

• High flame retardancy.

• Does not produce toxic or corrosive gases (environmentally friendly and non-toxic).

• Low smoke, halogen-free.

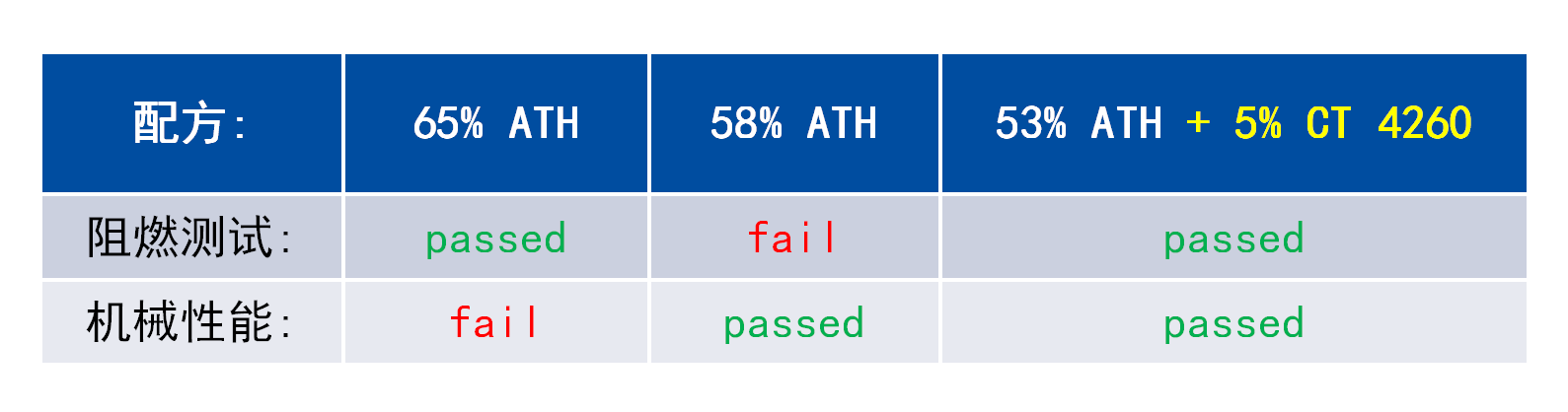

But to pass the V0 level flame retardant test, a typical aluminum hydroxide (ATH) concentration needs to be about 65%. The high ATH content in cables affects the mechanical properties, dispersion and melt flow properties, posing great challenges to cable material manufacturers.

03 BYK-MAX CT 4260 application examples

Halogen-free flame retardant cable material formula:

• Resin (Typical): LLDPE, EVA.

• Flame retardants: ATH, BYK-MAX CT 4260.

• Auxiliaries: antioxidants, processing aids, coupling agents, compatibilizers, etc.

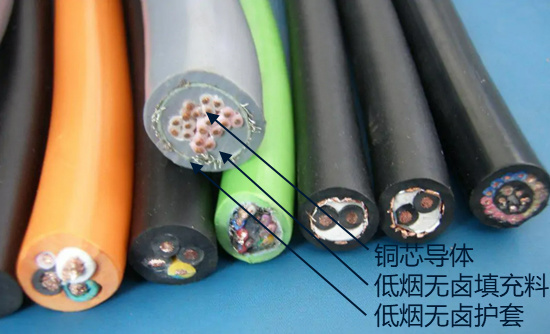

Application: Cable sheathing.

Test Results:

Processing conditions: twin-screw extruder for granulation, tablet press for tableting, tableting thickness is 2 mm.

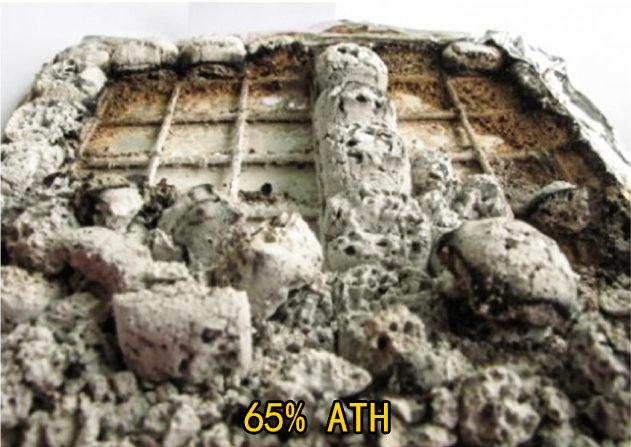

BYK-MAX CT 4260 can be used as an anti-drip agent in combination with mineral-based flame retardants such as ATH (aluminum hydroxide) and MDH (magnesium hydroxide).

BYK-MAX CT 4260 is used as a char-forming agent in combination with mineral-based flame retardants such as ATH (aluminum hydroxide) and MDH (magnesium hydroxide).

0 4 BYK-MAX CT 4260 typical parameters:

Q&A

Q: In addition to being used as a flame retardant synergist in wires and cables, BYK clay additives have other uses?

⑵Lightweight PP, PA and other composite materials/reinforcement functions.

⑶Incompatible blended plastics (as solid compatibilizer).