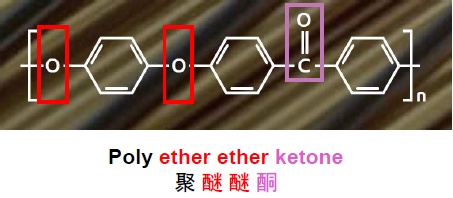

Products丨Evonik VESTAKEEP® polyetheretherketone application introduction

Release Time:

2023-11-15

Evonik VESTAKEEP® polyetheretherketone is a semi-crystalline high-performance plastic. Polyetheretherketone is widely used because of its outstanding performance and easy processability.

01 The characteristics of this material are as follows:

High temperature resistance: long-term temperature resistance, short-term temperature resistance above 300 degrees.

Chemical resistance: Resistant to most organic and inorganic chemicals, only soluble in concentrated sulfuric acid.

Hydrolysis resistance: resistant to hot steam at 250 degrees.

Wear resistance: excellent tribological properties, low friction coefficient.

Flame retardant: UL94 V0 natural flame retardant, low smoke and low toxic gas release.

Fatigue resistance: high fatigue resistance, suitable for replacing metals.

Non-toxic: FDA compliant and biocompatible.

Radiation resistance: No embrittlement problem under high radiation intensity.

Based on the above characteristics, this type of product has a wide range of application cases and prospects in many industries such as aviation, automobiles, petrochemicals, composite materials, machinery, consumer goods, semiconductors, and medical care.

02 Partial application display:

Typical applications of VESTAKEEP® in the aviation field help aircraft reduce weight and save energy:

It has applications in engines, assembly components, one-way belts, seats, interiors, pipelines, cables, etc.

Applications of VESTAKEEP® polyetheretherketone in the automotive industry:

Automotive rotors, gears, rollers, bearing frames and other parts.

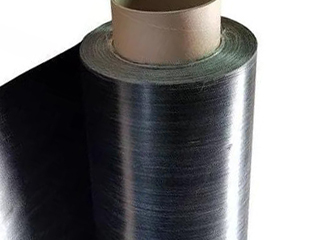

Application of VESTAKEEP® polyetheretherketone in composite materials:

One-way tape, thermoplastic composite, epoxy composite toughening, composite bonding powder adhesive.

Typical models of VESTAKEEP® in the composite direction include:

VESTAKEEP® 2000 P (Powder 500μm)

VESTAKEEP® 2000 FP (Fine Powder 55μm)

VESTAKEEP® 2000 UFP (Ultra Fine Powder 10~20μm)