Products | Nouryon Expancel® Microspheres for Composite Materials

Release Time:

2023-11-15

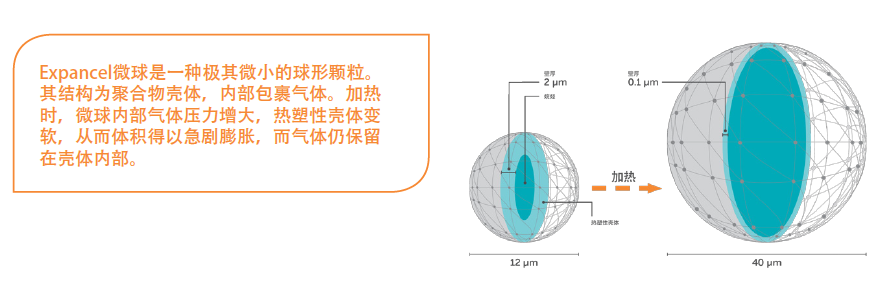

Foaming agent and lightweight filler combined into one; expands up to 60 times its original volume.

1. Highly controlled foaming process;

2. Uniformly closed cell structure;

3. Low density;

4. Extraordinary elasticity/impact resistance;

5. Smooth surface effect;

6. Excellent system compatibility.

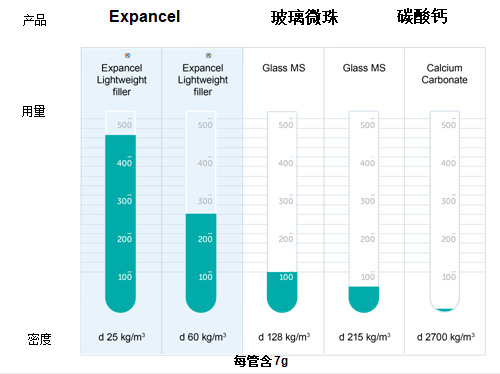

[2] Comparison of Expancel® microspheres with other lightweight fillers:

Lighter and more cost-effective

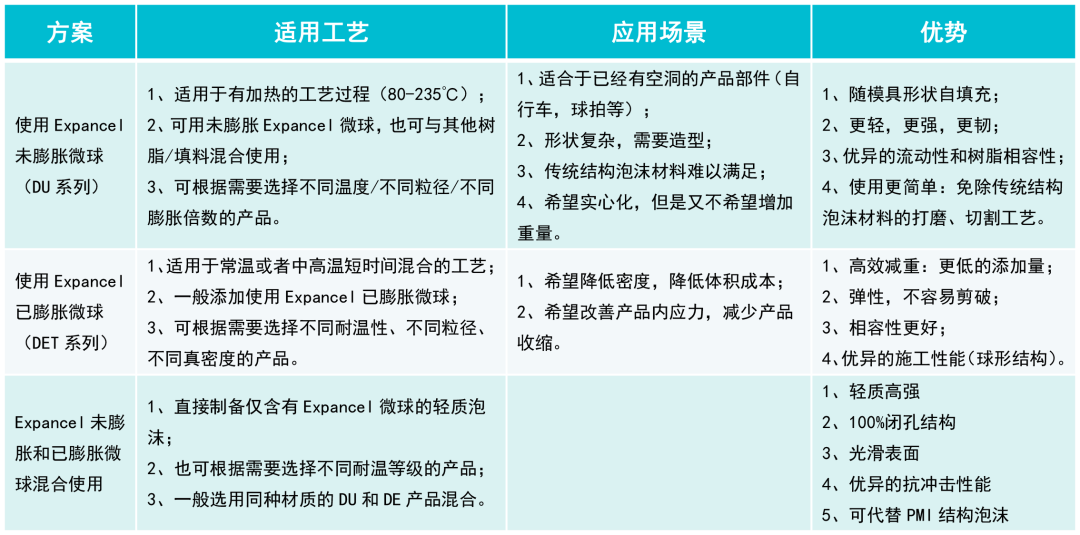

[3] Three uses of Expancel® microspheres in the composite industry

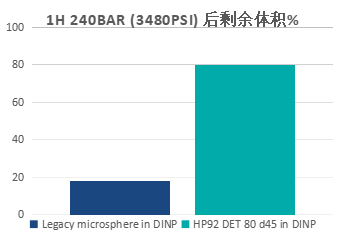

[4] Nouryon Expancel® microspheres are specially recommended—HP series

The excellent stability of Expancel® HP92 even after pressurization in DINP has a volume recovery rate that is more than 4 times that of conventional products.

Q&A

Question: Are the microspheres easily dispersed in the system?

Answer: 1. The true density of unexpanded microspheres: 1.1-1.2g/m³, which is not much different from the true density of resin, and there is no dispersion problem. 2. The true density of expanded microspheres: 0.025 g/m³, which is quite different from other resin systems and prone to floating. The viscosity of the system needs to be adjusted, and BYK dispersant can be used.

Q: What is the recommended amount of microspheres added to the system? Are there any system compatibility issues?

Answer: 1. The amount of unexpanded microspheres added to the system is about 3%. 2. The amount of expanded microspheres added to the system is: 0.3-0.5%. 3. At such a low addition amount, the microspheres basically have no system compatibility problems, and no special treatment is required for compatibility.