産(chǎn)品丨海逸在新(xīn)能(néng)源聚氨酯電(diàn)池膠中(zhōng)新(xīn)産(chǎn)品來了

發布時間:

2023-05-12

新(xīn)能(néng)源電(diàn)池膠中(zhōng)兩個原材料的推薦

目前膠粘劑下遊應用(yòng)中(zhōng),和新(xīn)能(néng)源汽車(chē)相關的應用(yòng)是目前最活躍,發展前景最好的一個市場。特别是新(xīn)能(néng)源汽車(chē)電(diàn)池中(zhōng)應用(yòng)于導熱模塊的膠粘劑,被認為(wèi)是新(xīn)能(néng)源汽車(chē)用(yòng)膠的核心産(chǎn)品。聚氨酯類型的膠在廣泛使用(yòng),這中(zhōng)間既有(yǒu)灌封的應用(yòng),也有(yǒu)結構粘接的應用(yòng),基本都以雙組份體(tǐ)系為(wèi)主。

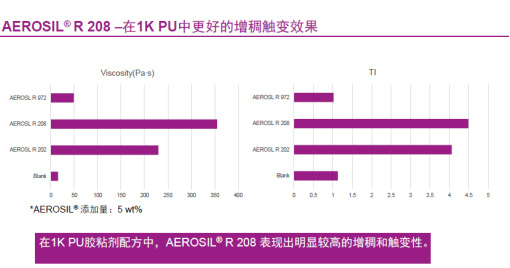

一、針對聚氨酯電(diàn)池膠裏新(xīn)型抗流挂要求,赢創推出了新(xīn)型氣相法二氧化矽AEROSIL® R 208

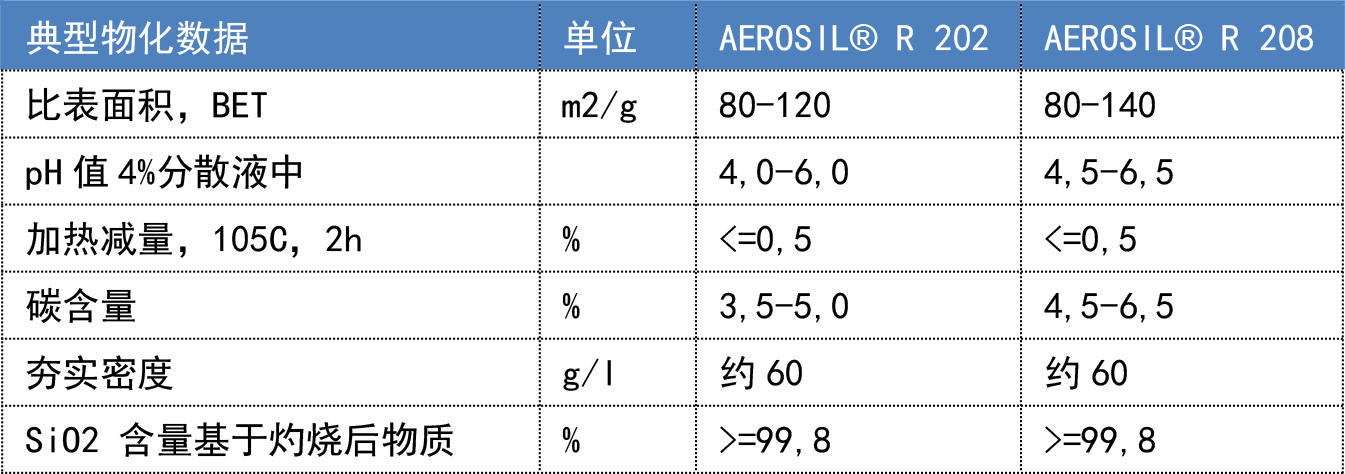

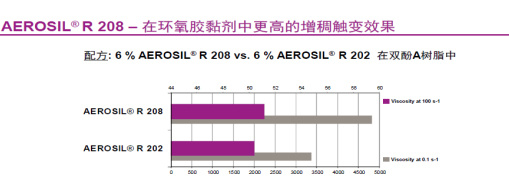

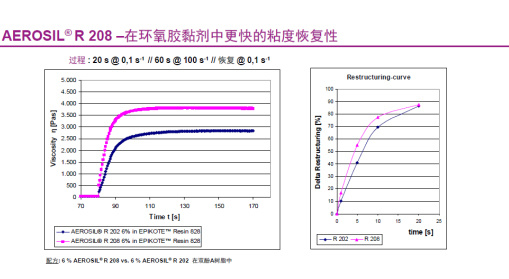

聚氨酯電(diàn)池膠因為(wèi)裏面添加了大量的導熱阻燃填料,對于抗流挂,防沉降會有(yǒu)更高的需求,針對上述情況赢創公(gōng)司提供了具(jù)有(yǒu)優秀的抗流挂、防沉降以及很(hěn)好的穩定性的超高疏水的氣矽AEROSIL® R 208。和之前的經典産(chǎn)品AEROSIL® R 202比較,二者有(yǒu)相同的處理(lǐ)劑,但是208具(jù)有(yǒu)更高的比表面積和處理(lǐ)程度。具(jù)體(tǐ)的技(jì )術指标對比如下:

體(tǐ)現在具(jù)體(tǐ)應用(yòng)中(zhōng)的區(qū)别如下:

另外AEROSIL系列氣矽在膠粘劑和密封膠中(zhōng)可(kě)以顯著提升性能(néng),具(jù)體(tǐ)如下:粘度控制、觸變性、防垂流、防沉降、噴塗性、補強、 粘接強度、儲存穩定性、透明性。根據不同的樹脂體(tǐ)系和不同的下遊客戶的需求,赢創的AEROSIL系列氣矽可(kě)以提供個性化的解決方案。如果需要了解更多(duō)的關于赢創氣矽在膠粘劑中(zhōng)的使用(yòng),請關注我們的公(gōng)衆号,後續會有(yǒu)更多(duō)的關于産(chǎn)品的介紹。

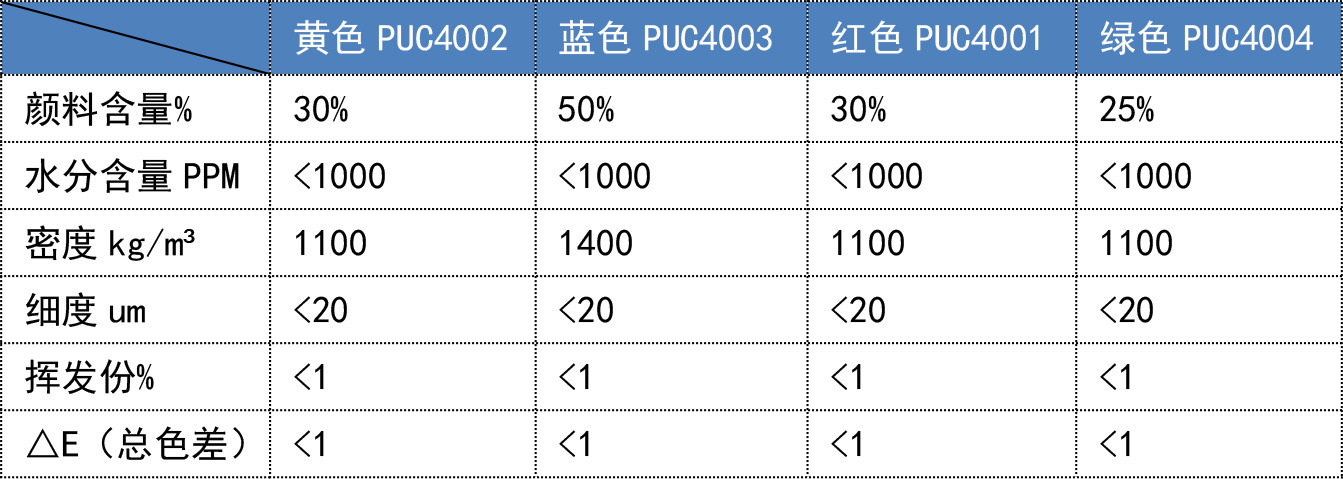

二、針對這些雙組份的聚氨酯膠,加聖推出了專用(yòng)色漿PUC4001-4004

産(chǎn)品介紹:此系列色漿為(wèi)高級顔料分(fēn)散在大分(fēn)子惰性酯中(zhōng)的混合液。環境友好,符合低氣味、低VOC排放等要求,符合歐盟RoHS法規。适用(yòng)于聚氨酯雙組分(fēn)室溫固化膠粘劑。具(jù)有(yǒu)優 良的耐溫和耐曬性能(néng)。

産(chǎn)品性能(néng)特點:

1.能(néng)保持較好的剪切流動性,易于添加,不會沉降;

2.細度較高,相容性好,分(fēn)散性更好,色澤更均一;

3.此濃縮度高,能(néng)在低添加量下有(yǒu)較好的着色表現;

4.水含量低,不會影響聚氨酯膠本身的操作(zuò)時間和特性。

如果對上述産(chǎn)品有(yǒu)興趣,可(kě)以咨詢當地銷售人員索要産(chǎn)品資料并且提供樣品。

版權所有(yǒu) © 2022 上海海逸科(kē)貿有(yǒu)限公(gōng)司