展會丨“深”情相約,海逸企業亮相深圳國(guó)際電(diàn)池展

發布時間:

2023-05-23

5月16日,第十五屆深圳國(guó)際電(diàn)池技(jì )術交流會/展覽會(CIBF2023)在深圳國(guó)際會展中(zhōng)心(寶安(ān)新(xīn)館)隆重開幕。截至昨日展會落幕,入場參觀總人次突破了30萬人次,創曆史新(xīn)高。

“深”情相約,海逸展會現場

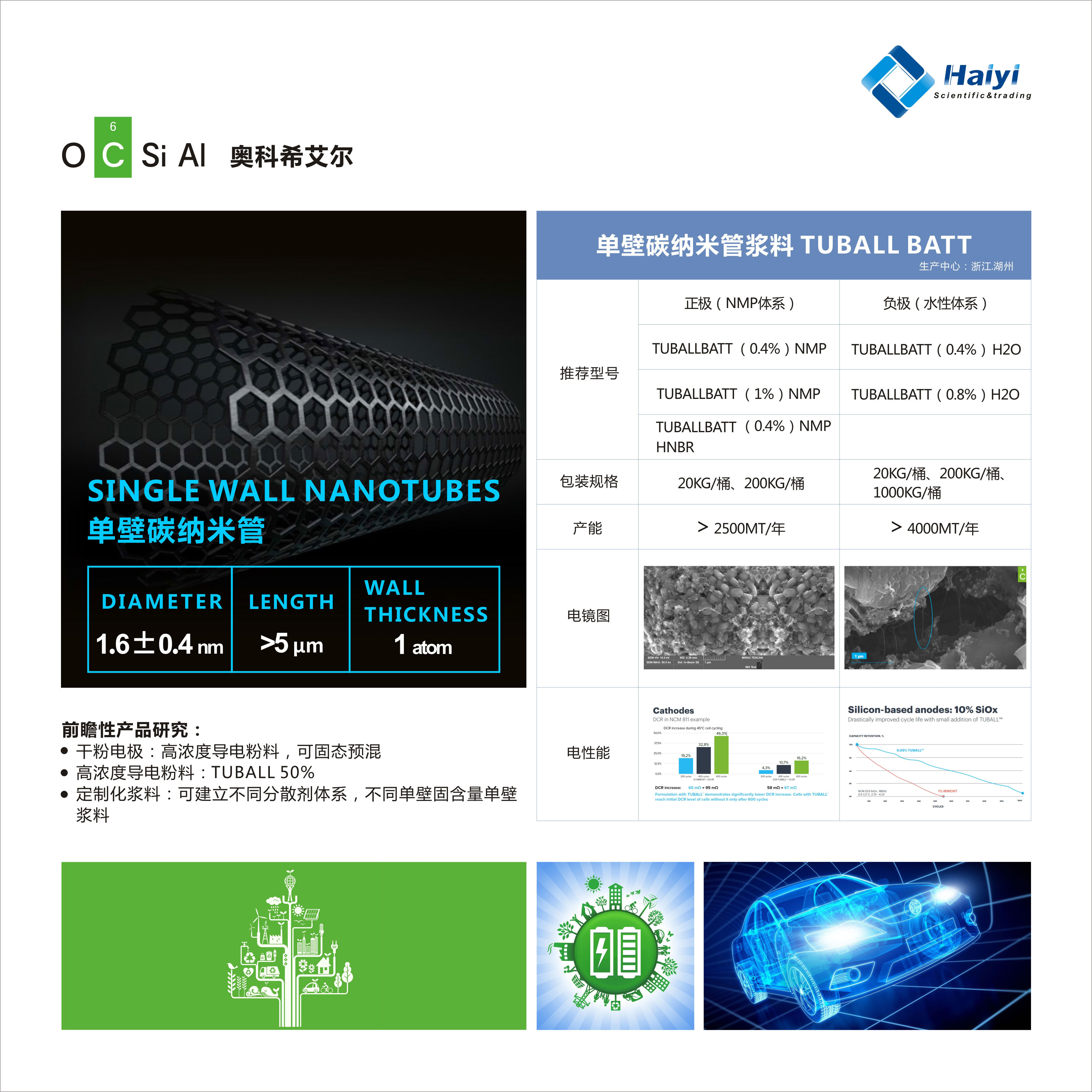

産(chǎn)品推薦:

本次展會海逸企業亮相衆多(duō)電(diàn)池行業國(guó)内外知名(míng)品牌的明星産(chǎn)品。

版權所有(yǒu) © 2022 上海海逸科(kē)貿有(yǒu)限公(gōng)司