Product丨Application of IMERYS superconducting carbon black in lithium batteries

Release Time:

2024-06-28

background story

When making the positive and negative electrodes of lithium-ion batteries, a certain amount of conductive agent is usually added to accelerate the rate of electron movement. At the same time, it can also effectively increase the migration rate of lithium ions in the electrode material, thereby improving the battery's charge and discharge efficiency (rate performance), reducing the battery's internal resistance and increasing capacity (conductive performance). The main performance parameters of conductive carbon black are: primary particle size, branched chain structure, specific surface area (BET), oil absorption value (DBP), etc.

With the development of lithium battery market, lithium battery is developing towards higher energy density and higher rate performance, so it is necessary to add less conductive agent with better conductivity. With the increasing development of dispersion equipment and auxiliary dispersion aids, the dispersion problem of high specific surface area and high structure superconducting carbon black has been basically solved, and the demand for superconducting carbon black in mid-to-high-end lithium batteries is increasing year by year.

product description

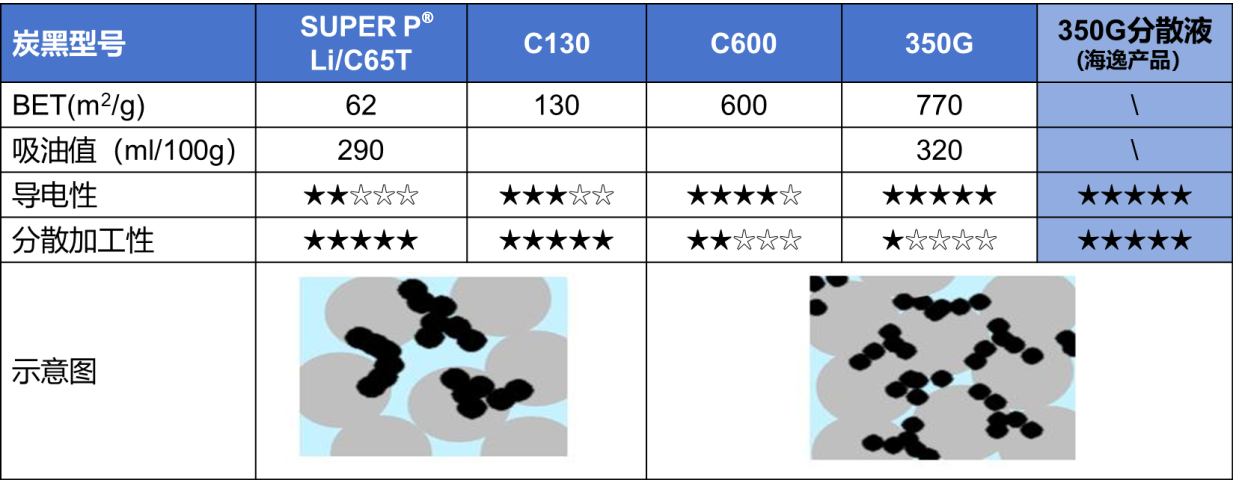

IMERYS's conductive carbon black SUPER P ® Li and conductive graphite KS6 have been widely used in the lithium battery industry. At the same time, IMERYS has been paying attention to the market development of superconducting carbon black. In addition to superconducting carbon black ENSACO ® 350G, it has also developed high specific surface carbon black products C130 and C600 for lithium battery applications. Compared with SUPER P ® Li, they have better conductivity and a lower addition ratio under the same conductivity. Among them, the addition amount of 130T is 60-80% of SUPER P ® Li, and the addition amount of ENSACO ® 350G and C600 is only 40-60% of SUPER P ® Li . As shown in the following table:

Note: Due to the high branched structure and small primary particle size of superconducting carbon black 350G, it is difficult to disperse in battery slurry. In order to solve the pulping process problems of customers, our company (Shanghai Haiyi Technology and Trade Co., Ltd.) can provide dispersed 350G dispersion (using NMP solvent, effective carbon black solid content ≥12%).

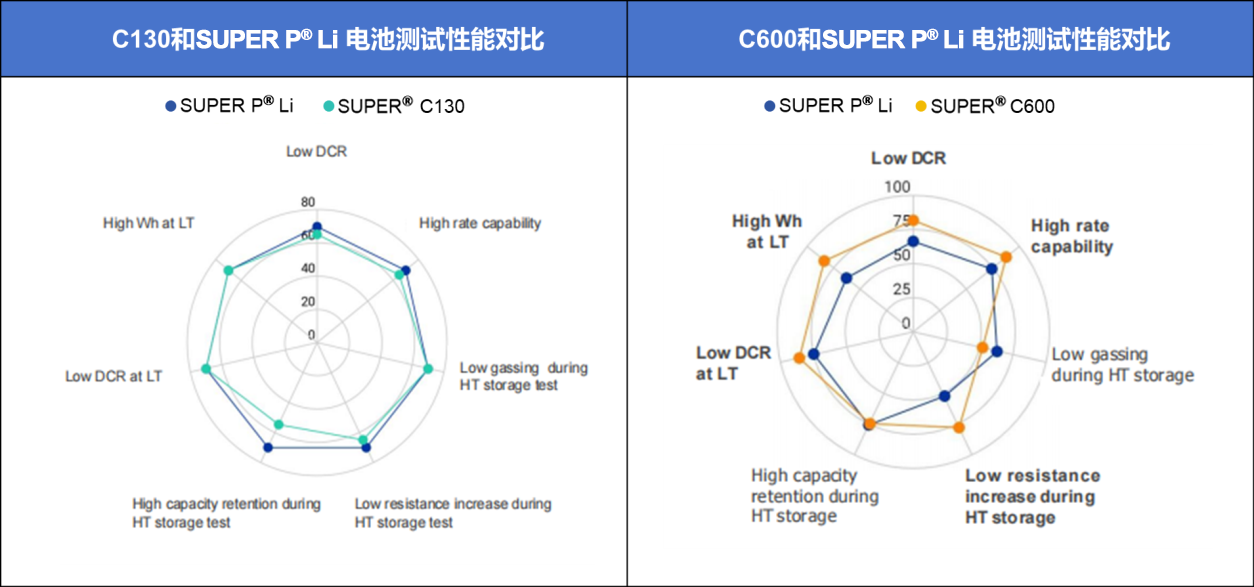

1. Comparison of electrical performance test of C130, C600 and SUPER P ® Li carbon black:

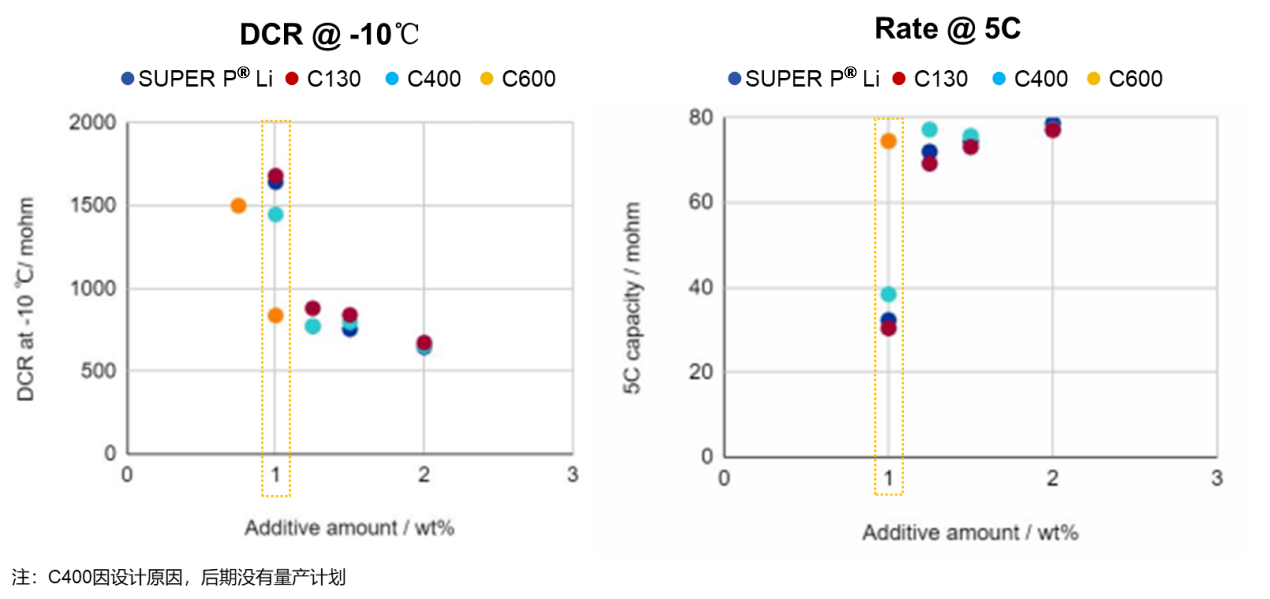

2. Comparison of electrical performance test of C1 30, C600 and SUPER P ® Li at different addition amounts:

As shown in the figure above, when carbon black is in an unsaturated state in the battery pole piece (at a low addition amount), the cell DCR and rate performance corresponding to C600 superconducting carbon black are optimal. The less carbon black is added to the pole piece, the more obvious the conductive advantages of C600 and C130 carbon blacks are. The difference in effect will only be apparent when the addition amount of C130 and SUPER P ® Li is less than 1%. When too much carbon black is added, different carbon blacks can build a complete conductive network, and the difference in conductive effect is relatively small.

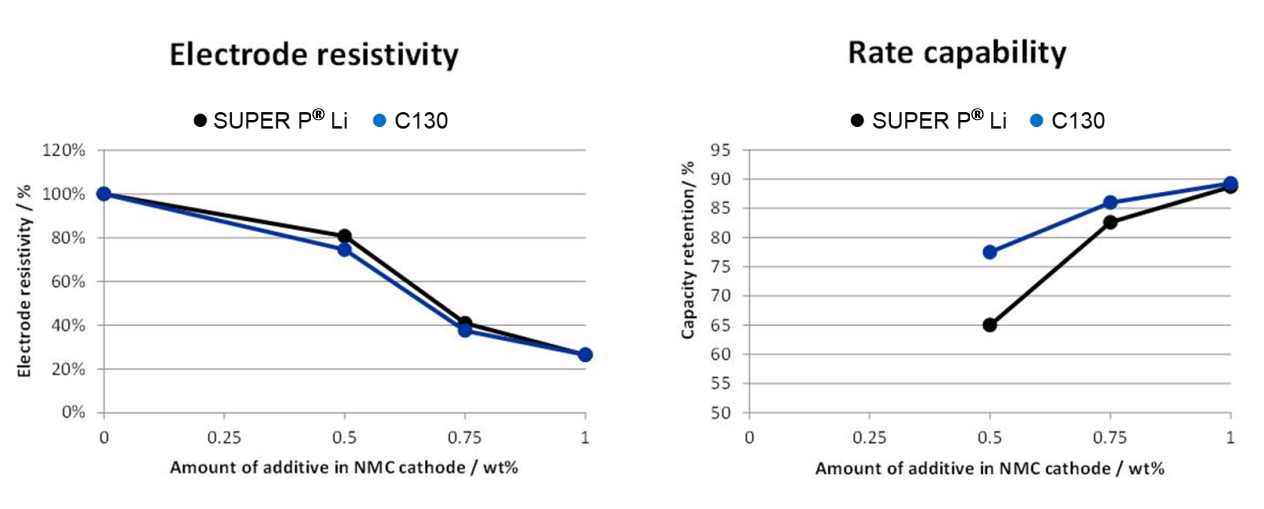

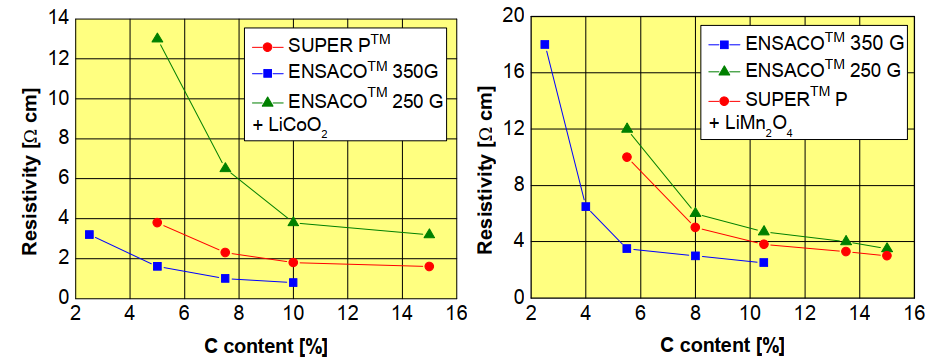

3. Resistance test comparison between superconducting carbon black 350G and conventional conductive carbon black SUPER P ® Li :

Summarize

Through the above description and comparative data analysis, the use of C130, C600 and 350G in the battery cell can improve the rate performance and battery energy density of the lithium battery. C130, C600 and 350G carbon black products with higher specific gravity and higher structure are more suitable for high energy density and high rate battery products, which meet the needs of lithium battery performance development and provide material support for the improvement of lithium battery performance.