Product丨BYK-MAX CT 4260—B1-grade low-smoke halogen-free cable material synergistic flame retardant solution

Release Time:

2024-08-02

With the official implementation of the national mandatory standard GB 31247-2014 on September 1, 2015, and the mandatory implementation of the EU cable CPR certification on July 1, 2017, the implementation of this regulation has led to higher and higher requirements for flame retardancy and environmental protection of cable materials, especially for high-altitude building cables and fire alarm cables used in public dense places (related to life and property safety). Therefore, how to quickly form carbon and improve the hardness of the carbon layer has become the primary challenge faced by low-smoke halogen-free cable materials.

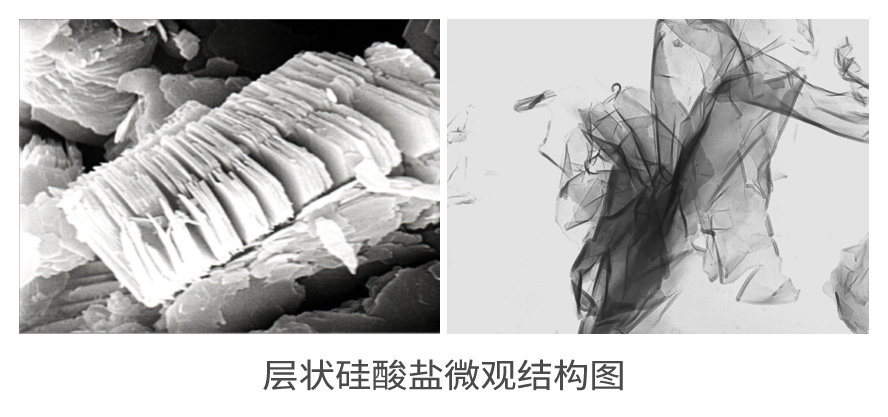

As one of the world's leading suppliers of thermoplastic additives, BYK's layered silicate series products are highly regarded in the industry. In order to meet the above regulatory requirements (known as B1 flame retardant in China), BYK BYK-MAX CT 4260 is a specially treated high-purity montmorillonite. The interlayer spacing of the treated montmorillonite becomes larger. At the same time, because the surface of the lamellae is covered by the long alkyl chains on the organic ions, the interlayer microenvironment is changed, and the inner and outer surfaces change from hydrophilic to lipophilic, which improves the compatibility of the polymer matrix and the monomer, and is conducive to the formation of polymer/layered silicate nanocomposites.

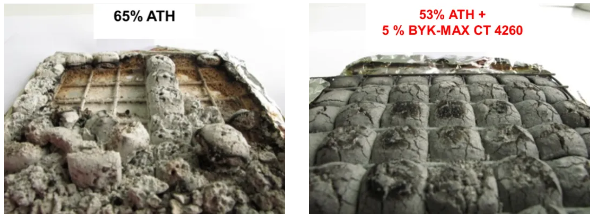

Based on the characteristics of BYK-MAX CT 4260 with large interlayer spacing, white color and easy dispersion, adding 1-3% in the PE/EVA system can be highly synergistic with ATH/MgH, reducing the amount of flame retardant added while improving the flame retardancy of the material. The rapid carbonization and high carbon layer hardness effectively prevent the cable from intensifying combustion, and can stably pass the carbon layer height FS <1.5m required by the domestic B1 flame retardant and reduce heat release.

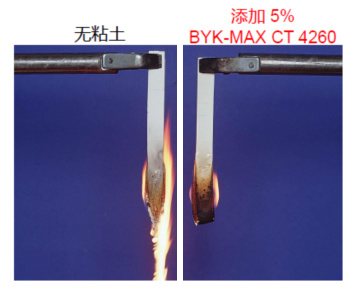

At the same time, BYK-MAX CT 4260, as a large-layer structure with a diameter-to-thickness ratio of 300-500, plays a "structural fixation" role after being evenly dispersed in the system. Macroscopically, it exhibits anti-drip characteristics, resulting in almost no combustion dripping during the combustion process, as shown in the following figure:

As a silicate with a layered structure, in order to ensure sufficient dispersion and avoid agglomeration and blockage, it is recommended to process it in the form of prefabricated masterbatch and side feeding during use. For cables that require VW-1 flame retardant requirements, a low addition of BYK-MAX CT 4260 within 1% can significantly improve the flame retardant "safety factor" and reduce the risk of flame retardant instability. Compared to commercially available montmorillonite and needle shaped structured sepiolite, BYK-MAX CT 4260 can achieve a certain degree of comprehensive cost reduction in a specific formulation system while exerting the same effect. In addition to BYK-MAX CT 4260, in order to meet the more differentiated requirements of different cable customers, BYK-MAX CLOISITE-20A is designed to be easier to disperse and has a significant effect on maintaining the fracture elongation and lower viscosity of the material; However, CLOISITE-SE 3000 has a lower water absorption rate compared to ordinary modified montmorillonite, which can significantly improve the volume resistivity.