Product丨Easily dispersible hydrophobic fumed silica-Evonik AEROSIL® E 972

Release Time:

2024-08-15

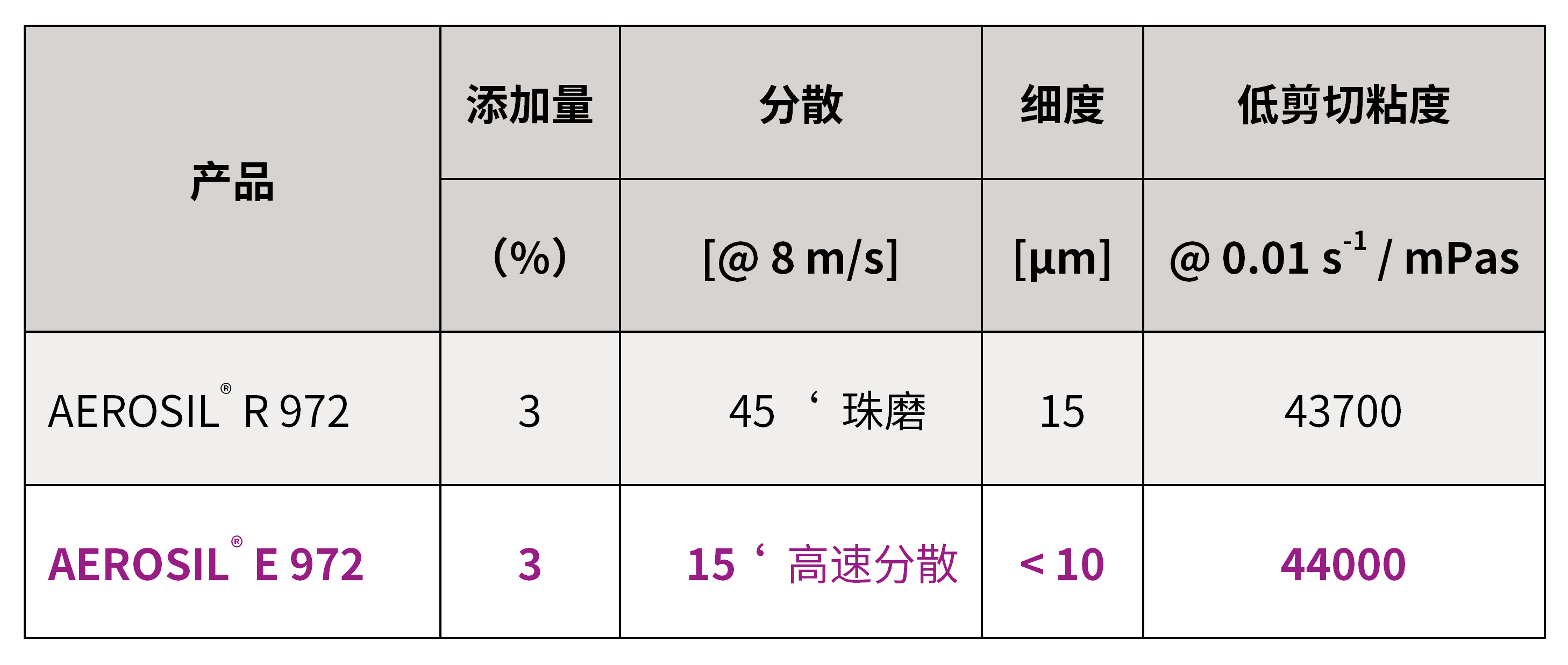

AEROSIL ® E 972 is a fumed silica post-treated with DDS (dimethyldichlorosilane). It is a highly efficient rheology modifier with a specific surface area of 85-135m 2 /g. Compared with the traditional AEROSIL ® R 972, this product is easier to disperse.

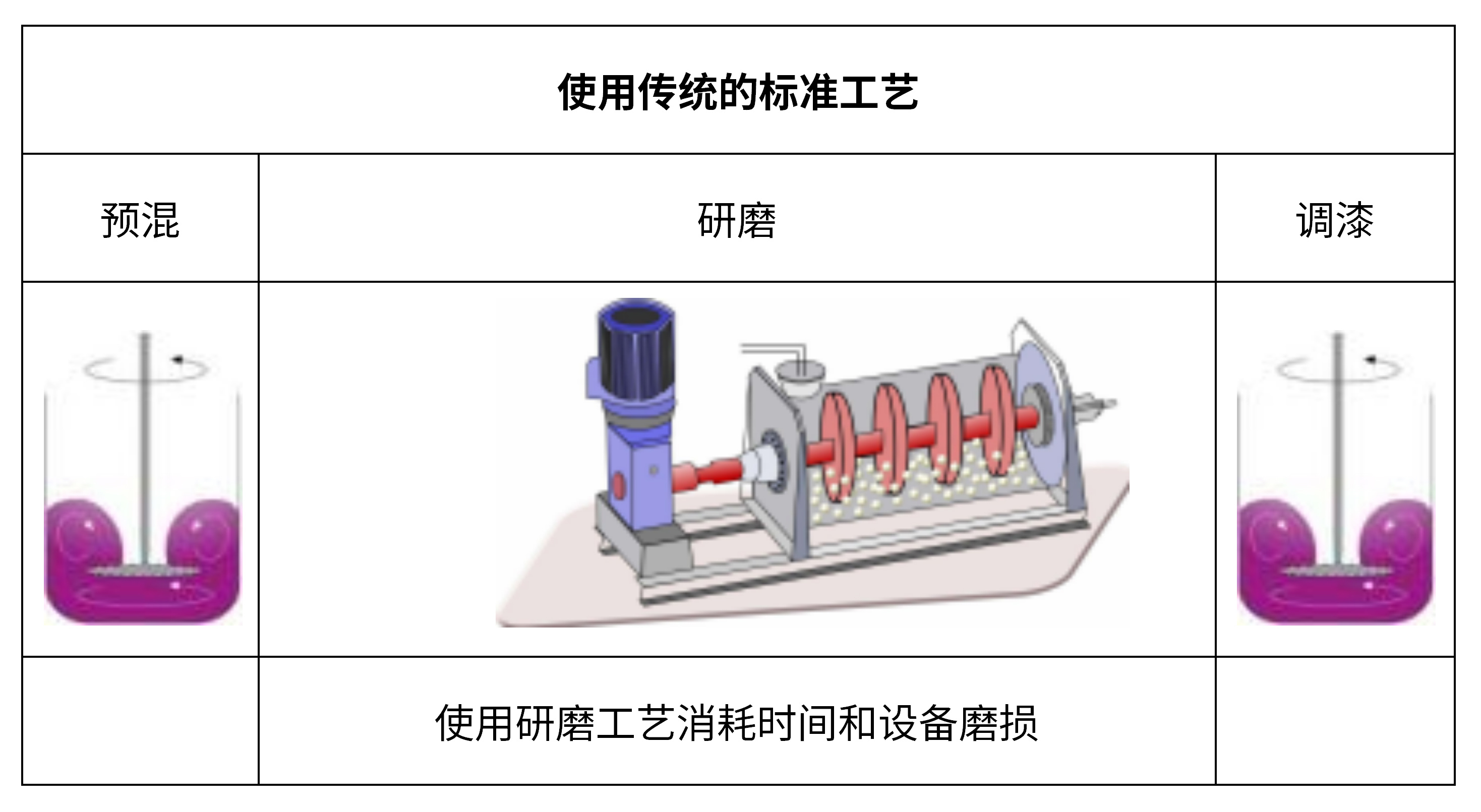

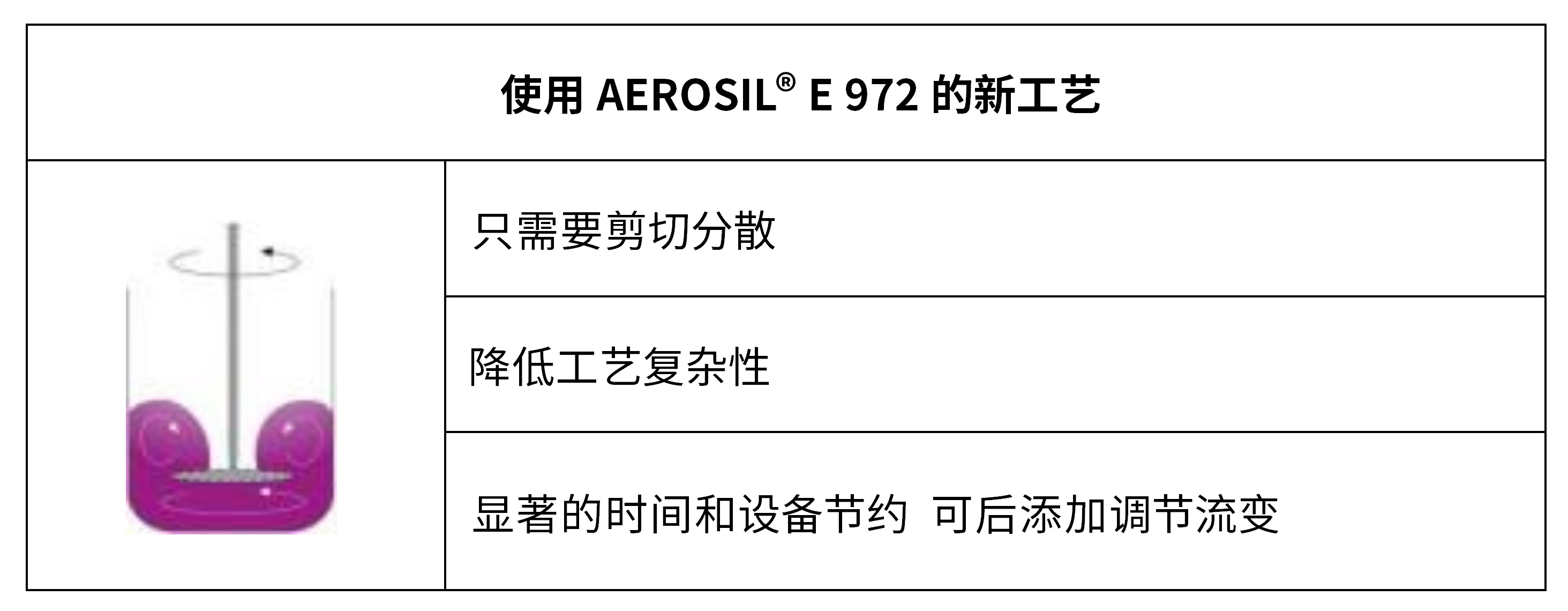

1) Reduce complex industries and improve production efficiency

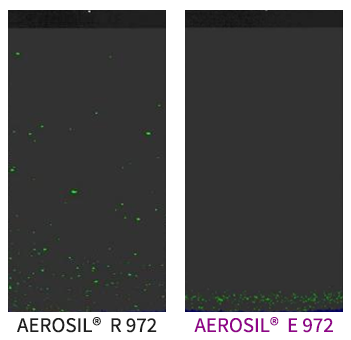

2) Excellent dispersibility and rheological properties

Comparison of board effects:

3) Excellent optical performance

Paint:

-

Solve the anti-sagging performance of spraying

-

The viscosity needs to be adjusted during the production and delivery stage, and can be adjusted by adding stirring later.

-

Sagging problems on construction sites require temporary solutions and can be improved by adding AEROSIL ® E 972

-

Helps prevent the color chips without grinding process from sinking

Varnish:

-

Can be directly dispersed with resin to solve the problem of anti-sulfur hanging

-

Helps matte varnish anti-settling and matte powder alignment

-

Can improve the hydrophobicity and water resistance of varnish

Questions and Answers:

1. What is the high-speed dispersion fineness of AEROSIL ® E 972?

Answer: At 1500rpm for 15 minutes, the high-speed dispersion fineness can be achieved below 15μm.

2. Is there anything special that I need to pay attention to when using AEROSIL ® E 972?

A: No; AEROSIL ® E 972 can be used by simply adding it to the premixing stage and stirring it at high speed for 15-20 minutes; if it needs to be added during the paint mixing stage, AEROSIL ® E 972 needs to be fully stirred into the paint at a low speed to form a vortex, and then the speed needs to be increased and dispersed for 15-20 minutes.