Evonik Silica in Textile Coatings

Release Time:

2021-09-15

In addition to excellent matting properties, Evonik silica matting powder also takes into account excellent dispersion, so it is widely used in the textile industry, including textile coatings, printing glue, PU films and other fields, such as the classic model ACEMATT® OK 412 .

Evonik's ACEMATT® product series matting powders are divided into two categories, namely precipitated silica matting powder and fumed silica matting powder. Both types of products are synthetic amorphous white fluffy powders. Compared with precipitated silica, fumed silica is more fluffy. HK represents precipitated silica without surface treatment (such as ACEMATT® HK 440), OK represents precipitated silica surface-treated with wax (such as ACEMATT® OK 412), and TS represents unsurfaced silica. Fumed silica (such as ACEMATT® TS 100), in addition, 3000 series (such as ACEMATT® 3300/3400/3600) are specially surface treated through the same process. All ACEMATT® products have a narrow particle size distribution, resulting in excellent dispersion.

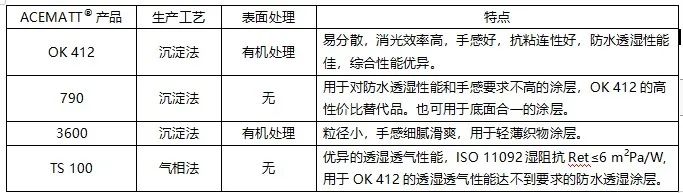

The main functions of silica matting powder in textile coatings are matting, anti-adhesion, improved hand feel and waterproof and breathable properties. The models involved include ACEMATT®OK 412, 790, 3600, TS100, etc. The relevant features are as follows:

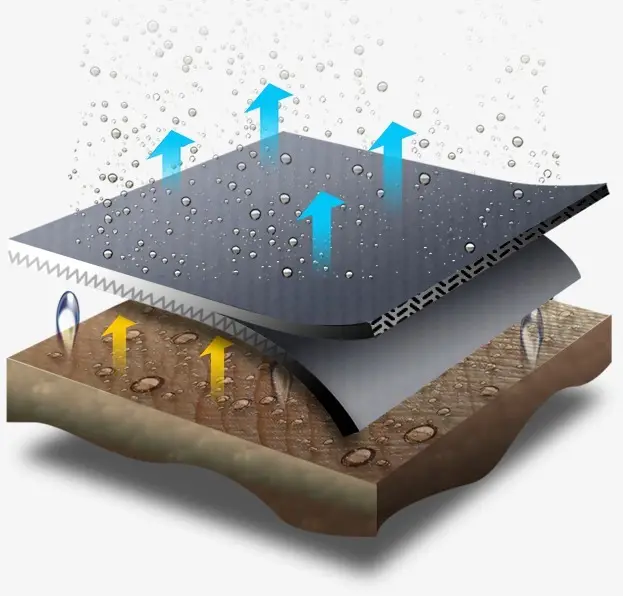

Currently, Evonik's silica matting powders used for waterproof and moisture-permeable coatings are mainly ACEMATT® OK 412 and ACEMATT®TS 100. Among them, ACEMATT®TS 100 has better moisture-permeable and breathable properties. This is because the silica matting powder is evenly distributed in the coating, causing the coating to form a microporous structure and improve the moisture permeability and air permeability. This has a lot to do with the production process, particle size, microstructure and shape of silica matting powder. The microporous structure of the coating containing ACEMATT® TS 100 is more uniform and compact, thus showing better moisture and air permeability.