Products | Sinochem International—UV absorber UV531

Release Time:

2021-09-15

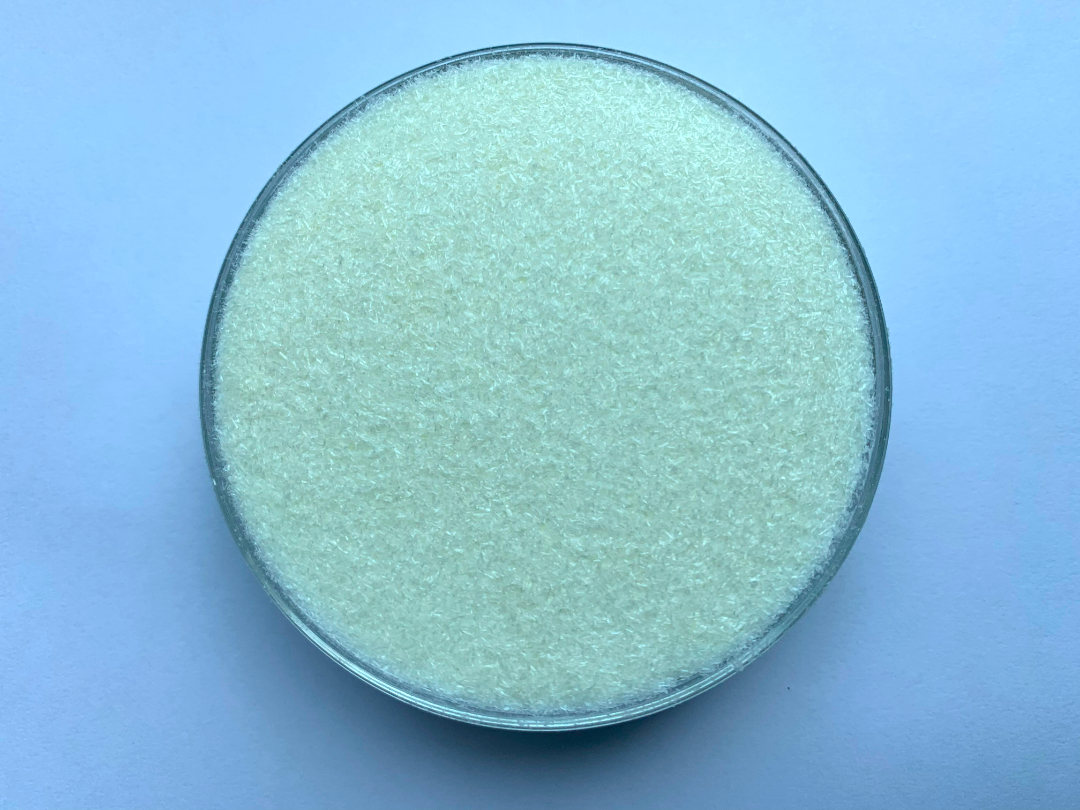

About Sinochem International (Fubia Chemical) FENTASORB 531

UV531

Sinochem International, a central enterprise in the chemical industry, completed the acquisition of Jiangsu Fubia Chemical Co., Ltd. on August 26, 2021. Fubia has a production capacity of 2,400 tons/year FENTASORB 531 UV absorber. The product has high purity (content: >99%) and good transparency. The normal addition amount does not affect the transparency of the product. It can be customized according to appearance requirements (flakes, large particles, etc.) to adapt to the production environment and process requirements. As a high-purity standard chemical, it can equally replace the components and content of UV531 products in existing formulas.

Product introduction of UV absorber UV531

There are a large number of unsaturated bonds, carbonyl groups, terminal hydroxyl groups and other functional groups in plastics that are easily broken and decomposed under the action of ultraviolet rays from the sun. Long-chain molecules turn into short-chain molecules, leading to phenomena such as powdering, brittleness, and cracking of the plastic surface.

In the processing industry of polymer materials such as plastics and rubber, light stabilizers must be added to plastic products for outdoor use to extend the service life of plastics outdoors.

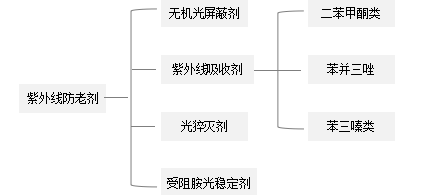

Light stabilizers are also called UV antioxidants and are classified according to different stabilizing mechanisms :

FENTASORB 531 belongs to the benzophenone compound (UV531 for short, scientific name is 2-hydroxy-4-n-octyloxybenzophenone).

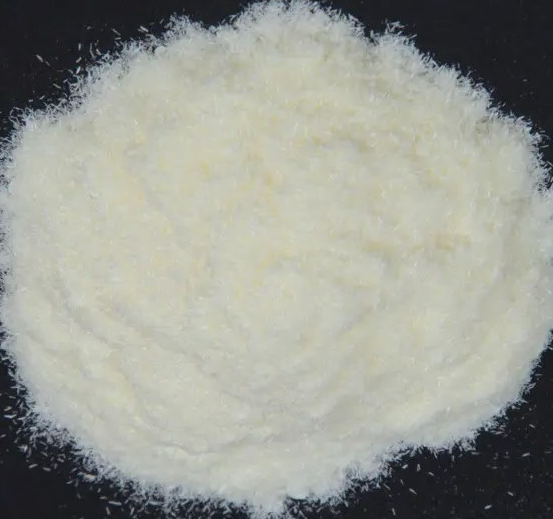

Appearance and properties: Light yellow or white needle-like crystalline powder, melting point: 48-49℃, flash point: 155℃, light transmittance: 450nm 94%Min, 500nm, 97%Min, belonging to the UV-B ≈ UV-A range Absorber (240-340nm, absorption is particularly strong at 270-330nm).

UV531 is a high-efficiency anti-aging additive with excellent performance. It is specially used in outdoor products. It has stable performance and can be used in plastic packaging materials in contact with food and children's plastics. It has light color, non-toxicity, good compatibility and low migration. , easy to process and other characteristics.

It provides maximum protection of polymers and helps reduce color while delaying yellowing and retarding loss of physical properties. It is widely used in PE, PVC, PP, PS, ABS, polyurethane, rubber products, etc. The general dosage is 0.1%-0.5%.

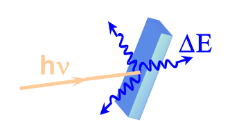

The mechanism of action of ultraviolet absorbers : absorb harmful ultraviolet energy and convert it into heat energy for release.

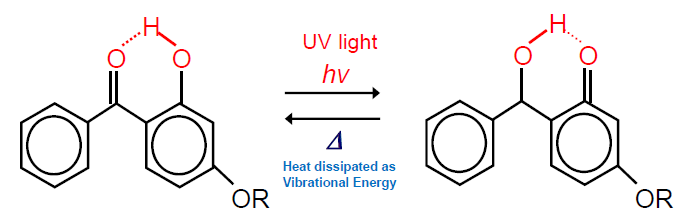

Explanation of the chemical reaction mechanism of UV absorbers :

The carbonyl group and hydroxyl group in molecules such as benzophenone derivative UV531 can produce intramolecular hydrogen bonds and form a chelate ring. When the molecule is exposed to ultraviolet rays, it absorbs energy, the thermal vibration of the molecule intensifies, and the intramolecular hydrogen bonds are destroyed, chelating The ring opens, converts ultraviolet light energy into heat energy, releases it, and then returns to the original molecular structure. Long-term use will not affect its performance, thereby preventing the polymer resin from absorbing ultraviolet energy and inducing photo-oxidation reactions.

UV531 itself has sufficient ability to absorb ultraviolet rays and also has high photostability.

——

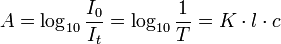

Quantitative analysis of effect: The theoretical value of UV absorber absorption efficiency follows Beer-Lambert's law

Beer–Lambert law

The physical meaning of Beer-Lambert's law: The absorbance A is directly proportional to the concentration C of the light-absorbing substance and the thickness of the absorbing layer ι.

Main characteristics of UV absorbers

-

Absorb UV rays

-

Convert harmful UV energy into heat

-

The use effect is related to the thickness of the product

-

Protective body

-

Effectively protects the contents of transparent products from UV rays that may cause them to lose efficacy

U V531 product features and selection rules

UV531 Product Features

UV-B and UV-A range absorption, product versatility, high cost performance, good transparency, low melting point, and good dispersion effect. The performance of soft products using PE and PVC is very outstanding, and the weather resistance is particularly outstanding in tropical areas.

Rules for selecting UV absorbers for plastic formulations UV531

1. When hindered amine light stabilizers are used in polymers under limited conditions, only UV absorbers and photoquenchers such as UV531 can be selected individually as weathering agents. But in most plastic and rubber products: AO + hindered amine light stabilization (HALS) + ultraviolet absorption (UV531, etc.) 0.5:1:1 ratio has a good synergistic effect.

2. Select according to the thickness of the product and the type of pigment in the formula. It is not recommended to use UV absorbers under these two conditions:

-

The product is very thin and transparent (≤0.1 mm).

-

Use carbon black black products with a color L value of 25 or less.

In addition to the above two types, any other kind of plastic products with natural color or added pigments and fillers can use UV absorbers such as UV531, especially in opaque products, which have outstanding effects.

3. PS, ABS, polyester, PC and other plastics that easily absorb ultraviolet rays must be added. Select the appropriate UV absorber according to the processing temperature.

Q&A

1

Is the function of UV531 one-time use? How long can it last?

Of course it is not a one-time use, it is a low-concentration and high-performance UV absorber. Mechanism of action: Absorbs harmful ultraviolet energy and converts it into heat energy, which can then be restored to its original structure.

Theoretically, it can cycle indefinitely, but after UV531 absorbs ultraviolet energy, the hydrogen bonds break and molecular isomerization occurs (called the enol structure). The hydrogen bonds will be captured by harmful peroxide free radicals, causing the performance of the ultraviolet absorber to fail. For stability and formula composition synergy, basic hindered phenolic antioxidants must be added. It is recommended to add hindered amine light stabilizers or a small amount of thiolipid auxiliary antioxidants.

2

What kind of addition method is used for UV531? What kind of addition combinations are commonly used?

Commonly used adding methods for UV531

-

Adding high-concentration masterbatch and resin raw materials to extrusion and injection molding products

-

Add directly using powder mixing process and then extrusion and granulation.

Add combination

-

Universal anti-UV masterbatch: 79% LDPE + 8% UV531 + 5% 326 + (6% titanium dioxide + 2% PE wax); conventional weathering formula: 0.1-0.3% phenolic antioxidant + 0.1-0.5% UV531.